Holidays during this time of year, when days are short, emphasize light. Hanukkah, the Jewish Festival of Light, commemorates the miracle of a one-day supply of oil miraculously lasting eight days during the Maccabees battle for freedom and allowing for the re-dedication of the Temple in Jerusalem. In Christianity, the Wise Men followed a bright star in order to find the baby Jesus and deliver their gifts. Pagan rituals from ancient times utilize bonfires in outdoor spaces. Holiday lights are seemingly everywhere, bringing light to the darkest days of winter.

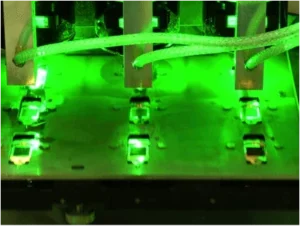

Light is an essential part of the holidays and at Potomac, light is part of our work year-round. Light generated by lasers is one of our main tools, providing unique laser material processing capabilities for advanced manufacturing.

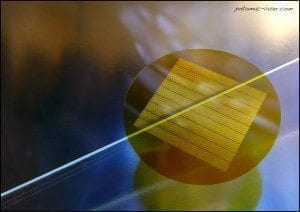

Laser light’s properties allow us to cut, drill, weld, and engrave parts, and our long history with ultraviolet [UV] light extends laser machining to specialized applications in the biotech, microfluidics, cancer research, pharmaceutical, and microelectronics industries. With UV light’s short wavelength, we can create features as small as one micron, creating opportunities for miniaturization of new products, especially in the implantable healthcare space.

Perhaps even more importantly, UV light interacts with materials in a way that generates no thermal damage and almost all matter absorbs short Excimer laser wavelengths of 248 and 193 nm. Potomac has expertise laser micromachining glass without cracking, marking hard materials such as diamond, and creating channels and holes for microfluidic devices in COC and PMMA. And we do it all with light.

Laser machines also integrate beautifully with other tools like 3D Printing, micro-CNC milling, bonding, replication from molds and new technologies yet to be invented. Choosing the optimal tool for a job is key to success manufacturing the best parts for our customers, yet light does hold a special place in the Potomac toolbox!

As you enjoy the holidays that celebrate light and its importance in our lives, Potomac wishes everyone a year filled with Light in the world!