Potomac Photonics laser micromachines small windows in glass to support research at the UT MD Anderson Cancer Center.

Asthma is one of the leading health conditions in the world. According to the US Centers for Disease Control there are 18.7 million adults and an additional 6.8 million children living in the United States with the pulmonary condition. The cost to society from medical care, as well as lost school and work time, is high with an estimated half-million patients requiring hospitalization averaging approximately 4 days per stay per year.

Researchers in the Department of Pulmonary Medicine, The University of Texas MD Anderson Cancer Center, in Houston are studying how mucus production dysfunction contributes to asthma, as well as other diseases such as cystic fibrosis and chronic bronchitis. Their work centers on how airway mucus entraps inhaled particles and pathogens, clearing them from the lungs when Ciliary action propels mucus to the pharynx to be swallowed. Excessive mucus production in amount or density cannot be cleared by ciliary action, blocking airflow. In fact, the cause of death from asthma is actually suffocation.

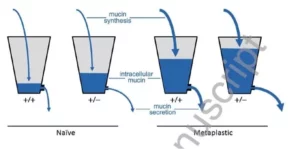

This diagram from a recent paper the group published in Bioscience Reports demonstrates: “the naïve un-inflamed condition with low mucin synthesis, illustrated with thin arrows of water flowing into the two left buckets, while the metaplastic inflamed condition with high mucin synthesis is illustrated with thick arrows flowing into the two right buckets. Buckets representing WT (+/+) mice have large outlets so that little water accumulates in the naïve condition and only a moderate amount in the metaplastic condition, while buckets representing SNAP23 Het (+/-) mice have small outlets so that some water accumulates even in the naïve condition and a large amount in the metaplastic condition. In all scenarios, hydrostatic pressure increases until steady state outflow matches inflow.”

This diagram from a recent paper the group published in Bioscience Reports demonstrates: “the naïve un-inflamed condition with low mucin synthesis, illustrated with thin arrows of water flowing into the two left buckets, while the metaplastic inflamed condition with high mucin synthesis is illustrated with thick arrows flowing into the two right buckets. Buckets representing WT (+/+) mice have large outlets so that little water accumulates in the naïve condition and only a moderate amount in the metaplastic condition, while buckets representing SNAP23 Het (+/-) mice have small outlets so that some water accumulates even in the naïve condition and a large amount in the metaplastic condition. In all scenarios, hydrostatic pressure increases until steady state outflow matches inflow.”

Dr. Michael Tuvim, Director of Laboratory Research, in the Department of Pulmonary Medicine explains that current research in the group is to study the machinery of mucus secretion with the goal of developing an assay in order to record mucus eruption in real time, which does not currently exist. Dr. Tuvim’s group is examining mice trachea that have been pre-stained with an orange fluorescent dye. With fluorescent detection techniques the researchers can stimulate baseline secretion, depleting the stores of mucus production and consequently stopping explosive secretion.

Prepared trachea samples must be mounted to a microscope slide with a coverslip containing a 2.5 x 2.5 mm window. Explains Dr. Tuvim, “Creating the small size of the window was prohibitive for traditional glass cutting methods. Potomac Photonics was one of the few companies that could meet our small size requirement and not damage the glass.”

Precision micromachining of glass is one of Potomac Photonic’s core competencies. Over the decades of working with glass, we’ve developed techniques and processes that give a clean edge without damage to the substrate. Whether cutting out windows or small hole drilling, Potomac’s work in glass is ideal for the high precision demands of biotech applications.