In a significant move that promises to revolutionize the field of micro-manufacturing and materials supply, Goodfellow has recently acquired Potomac Photonics. This acquisition is not just a merger of two companies; it’s a strategic integration that exemplifies the adage, “1+1=3.” Here’s why this combination is a game-changer for customers across various industries.

Expanding Horizons: From Micro-Machining to Material Supply

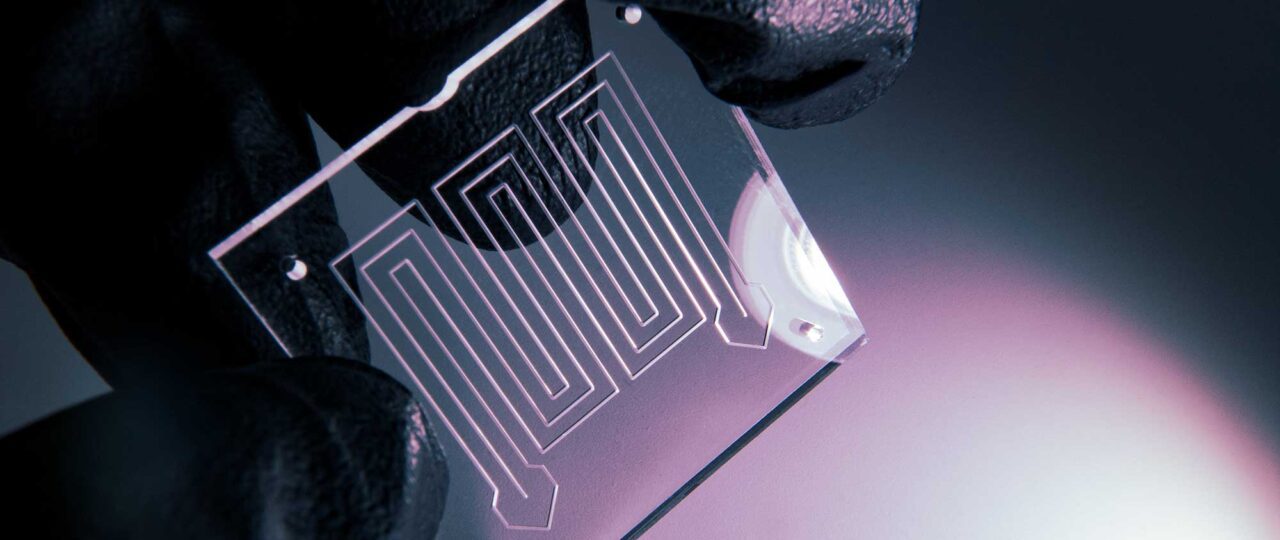

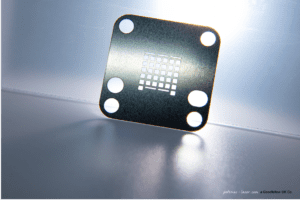

Potomac Photonics has long been a leader in micro-manufacturing services, offering precision laser micro-machining and other advanced manufacturing techniques. Their expertise in creating intricate designs in materials like polymers, metals, and ceramics has made them a go-to partner for industries ranging from medical devices to aerospace.

Goodfellow, on the other hand, is renowned for its extensive catalog of over 170,000 materials. Their portfolio includes metals, polymers, ceramics, and composites, available in various forms and specifications. With decades of experience, Goodfellow has been a trusted supplier for research, prototyping, and specialized manufacturing needs.

The Power of Integration: Why 1+1=3

The integration of Potomac Photonics’ cutting-edge micro-machining capabilities with Goodfellow’s vast material supply creates a synergy that enhances the value proposition for customers. Here’s how this combination makes the process more efficient and beneficial:

-

One-Stop Shop for Solutions: Customers can now access both micro-machining services and a comprehensive range of materials from a single source. This streamlined approach simplifies procurement, reduces lead times, and enhances project coordination.

-

Enhanced Efficiency: By leveraging the combined expertise and resources of both companies, customers can expect faster turnaround times and improved precision in their projects. The seamless integration of materials and machining processes minimizes errors and accelerates development cycles.

-

Broadened Capabilities: The expanded range of materials available through Goodfellow opens new possibilities for innovation in micro-manufacturing. Whether it’s developing new medical devices with biocompatible materials or creating aerospace components with high-performance alloys, the combined capabilities of Potomac and Goodfellow enable groundbreaking advancements.

Real-World Impact: Practical Benefits for Customers

Imagine a biotech company needing microfluidic channels in a specific polymer. With the combined forces of Potomac and Goodfellow, they can now source the exact material from Goodfellow’s extensive catalog and have Potomac precisely machine the intricate channels. This not only saves time but also ensures the highest quality and compatibility of the end product.

Similarly, a research lab working on advanced materials can now prototype and test new formulations with ease. Goodfellow’s diverse material offerings provide the necessary inputs, while Potomac’s micro-machining expertise enables precise and repeatable fabrication, facilitating rapid experimentation and innovation.

A Future of Innovation and Excellence

The acquisition of Potomac Photonics by Goodfellow marks a new era of efficiency, innovation, and excellence in the fields of micro-manufacturing and material supply. This strategic alliance is poised to deliver unparalleled value to customers, driving advancements across various industries and setting new standards for quality and service.