Potomac Expands its Leak Detection Hole Drilling Capabilities

Every pharmaceutical, food, and nutrition products manufacturer is faced with the challenge of making sure their products meet the highest quality standards.

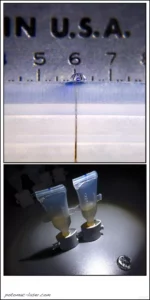

Container integrity is one of the major concerns when it comes to patient or consumer safety. If you are in the process of installing or recertifying leak test equipment on your production line, Potomac stands ready to provide you with the most accurate and cost-effective technology to drill precise holes as small as 1 micron.

Recently, Potomac has increased its Leak Test Calibration Hole Drilling capabilities with a new state of the art system capable of drilling holes in almost any material including glass, polymers, ceramics and metals. Our R&D Team is continually developing new advanced manufacturing technologies related to leak test calibration hole drilling in order to ensure our technology keeps up with the latest requirements of industries, such as pharmaceutical, medical device and food.

Potomac Engineers will work closely with you to understand your requirements and suggest the best and most cost-effective plan to ensure that your validation or recertification process is a success. We also work very closely with leak test detection equipment manufacturers to understand the requirements of their systems and where best to position the holes. Our holes are especially suited for technologies such as High Voltage Leak Detection Systems (HVLD) which is the preferred in-line test method for continuous leak testing on head and/or bottom areas of hermetically sealed plastic containers and ampoules containing sterile liquids. Parts with holes of micron sizes can be detected with a sufficiently high degree of reliability, even with liquids of low conductivity. HVLD systems meet the pharmaceutical industry’s and the authority’s current quality standards. Other techniques include vacuum/pressure decay testing and direct gas leak detection testing methods.

Leak Detection Calibration Hole Drilling specifications include:

- Holes as small as 1 micron

- Excellent Hole Diameter Repeatability

- Precise hole placement

- Capacity to handle small projects (10’s of parts to 10,000’s+ of parts)

- Rapid turnaround

Packaging forms that we can drill small holes into include Ampoules, Vials, Pouches, Blisterpacks, Syringes, Aerosol Sprays, Lids, Cans, Vacuum Sealed Packs, Filled and Sealed Bottles.

Potomac is ISO 9001 and ISO 13485 certified and provides a Certificate of Conformance with each shipment.

Please contact us today to discuss your Leak Detection Calibration Hole Drilling Requirements.