Introduction

DuPont’s Kapton polyimide is a high-performance polymer known for its exceptional electrical insulation, mechanical strength, and resistance to extreme temperatures and chemicals. As a result, it has become an indispensable material across various industries, including medical, biotech, electronics, aerospace, and automotive. In this blog post, we’ll discuss the diverse applications of Kapton in these industries and how Potomac Photonics has established itself as a leader in laser micro machining Kapton, offering rapid turn contract manufacturing and full-scale production services.

DuPont’s Kapton polyimide is a high-performance polymer known for its exceptional electrical insulation, mechanical strength, and resistance to extreme temperatures and chemicals. As a result, it has become an indispensable material across various industries, including medical, biotech, electronics, aerospace, and automotive. In this blog post, we’ll discuss the diverse applications of Kapton in these industries and how Potomac Photonics has established itself as a leader in laser micro machining Kapton, offering rapid turn contract manufacturing and full-scale production services.

DuPont Kapton Polyimide: A Material for Multiple Industries

-

Medical Industry: Kapton is widely used in the medical field due to its biocompatibility and stability. Some common applications include:

- Sensors: Used for measuring various physiological parameters, Kapton sensors offer excellent flexibility and biocompatibility.

- Catheters: Kapton’s durability and biocompatibility make it suitable for catheter construction, especially in demanding applications.

- Implantable Devices: Kapton’s stability and resistance to bodily fluids make it ideal for components in implantable devices such as pacemakers and neurostimulators.

-

Biotech Industry: In biotechnology, Kapton’s excellent electrical insulation and chemical resistance properties are critical. Some applications include:

- Microfluidic Devices: Kapton is used in the fabrication of microfluidic devices for precise control and manipulation of fluids at the microscale.

- Biosensors: Kapton’s stability and biocompatibility make it an excellent choice for biosensors used in diagnostic and monitoring applications.

-

Electronics Industry: The electronics sector relies on Kapton’s outstanding electrical insulation and thermal stability properties. Some common applications include:

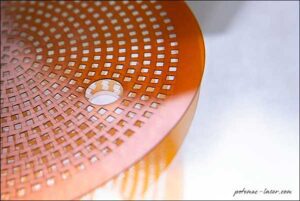

- Flexible Circuits: Kapton’s flexibility and durability make it ideal for creating thin, flexible circuits for use in various electronic devices.

- Insulation Layers: Kapton’s insulating properties make it suitable for use as an insulation layer in electronic devices, protecting components from electrical interference and thermal issues.

-

Aerospace Industry: The aerospace sector values Kapton for its ability to withstand extreme temperatures and harsh environments. Some typical applications include:

- Insulation Layers: Kapton’s excellent thermal and electrical properties make it suitable for insulation layers in spacecraft and aircraft, protecting sensitive components from extreme conditions.

- Gaskets: Kapton’s durability and resistance to harsh environments make it a popular choice for gaskets and seals in aerospace applications.

- Heat Shields: Kapton’s thermal stability allows it to be used in heat shields, protecting critical components from high temperatures.

-

Automotive Industry: With the increasing demand for electric vehicles and advanced electronics, Kapton has found a niche in the automotive industry. Some applications include:

- Battery Insulation: Kapton’s thermal and electrical properties make it suitable for insulating high-performance batteries in electric vehicles.

- Wire Harnesses: Kapton’s flexibility and durability make it an excellent choice for wire harnesses in automotive applications, providing reliable electrical connections.

- Sensors: Kapton’s stability and resistance to harsh environments make it ideal for automotive sensors that monitor critical vehicle parameters.

Rapid Turnaround and Unparalleled Responsiveness

Potomac Photonics focuses on providing responsive, high-quality, and cost-effective solutions for their clients. With lead times for Kapton projects typically less than a week and, in some cases, as fast as 24 hours, their commitment to customer satisfaction is evident. This rapid turnaround time sets them apart in the industry, making them a preferred partner for companies that require precision and speed.

A Dedicated Team Driving Innovation

Potomac Photonics’ dedicated team is focused on developing new manufacturing technologies driven by market demand. By staying ahead of the curve and continuously innovating, they ensure that their clients receive the best solutions for their specific needs. Their unwavering commitment to delighting customers has helped them maintain their position as a leader in laser micro machining Kapton and other high-performance materials.

Conclusion

DuPont Kapton polyimide has become an essential material across various industries, including medical, biotech, electronics, aerospace, and automotive. Potomac Photonics’ expertise in laser micro machining Kapton, coupled with their rapid turnaround times and commitment to innovation, make them a go-to partner for companies seeking precision, quality, and responsiveness in manufacturing. As the demand for high-performance materials like Kapton continues to grow, Potomac Photonics’ dedication to customer satisfaction and technological innovation will undoubtedly keep them at the forefront of the industry.