High-throughput continuous cell-based screening has several benefits from current conventional plate-based methods. The unique liquid handling capabilities offered through microfluidic systems has provided an opportunity to explore and screen several hundreds of thousands of cells in a matter a of a few minutes or hours with 1000-fold less reagents(1-3) .

Droplet-based microfluidic systems are becoming established as valuable tools for various applications that require multistep biological and chemical assays. Single-cell genomic sequencing has recently emerged as a powerful tool for mapping cellular heterogeneity in both diseased and healthy tissues. Droplet microfluidics is among the most promising candidates for capturing and processing thousands of these individual cells for whole-transcriptome or genomic analysis in a massively parallel manner with minimal reagent use. A particular advantage of droplet-based microfluidics when compared with conventional analysis or screening methods is that the droplet provides the ability to link genotype with phenotype through the method of compartmentalization since each droplet behaves as an isolated reactor that encloses individual cells that can be easily manipulated and from which genomic information is readily obtained. Molecules of interest remain trapped inside the droplet and are available for analysis and sorting allowing for efficient barcoding and accuracy of analysis.

Potomac is pioneering new microfabrication technologies that allow for rapid prototyping of different droplet microfluidic design concepts using high-performance materials suitable for scale-up to industrial manufacturing. In the next section we will discuss the design and manufacturing of these highly versatile microfluidic chips.

Droplet Microfluidic Chip Design

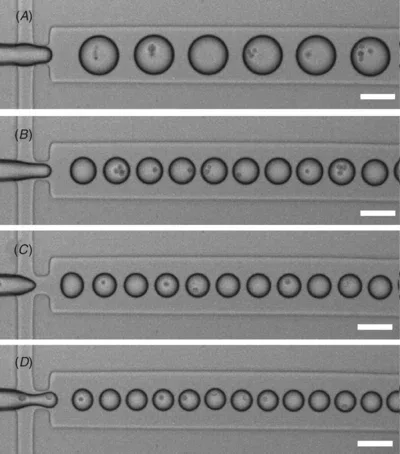

In order to realize the benefits of droplet microfluidics, the microfluidic chip must be designed as a “droplet generator”. Droplets are typically generated by creating two liquid phases, one of which is an oil phase and the second of which is typically an aqueous phase. One of the phases is designated by the designer as the continuous phase while the other is the dispersed phase. Droplets are produced by incorporating channels and features in the microfluidic device that create the required hydrodynamic conditions for droplet formation, and the droplet formation process depends strongly on the interaction of flow rate, liquid physical properties and the geometry of the features on the chip(4) . The feature designs are typically classified as “co-flow”, “cross flow” and “flow focusing”. Co-flow is achieved using coaxial microchannels where the continuous phase flows in an outer concentric channel and the dispersed phase flows in the inner channel, both in the same direction. In the crossflow design the dispersed and continuous phases meet at an angle formed by fabricating intersecting microfluidic flow channels. The most common case is the T-junction, where dispersed and continuous phases converge in perpendicular channels. Other microfluidic channel designs for producing droplets via crossflow include the “K-junction” and the “V-junction”. Finally flow focusing designs incorporate a microfluidic contraction region through which coaxial immiscible streams flow and subsequently exit to a single microchannel resulting in the creation of uniform droplets. This method allows for making very small droplets as the formation process is closely related to the size of the narrow contraction.

In order to realize the benefits of droplet microfluidics, the microfluidic chip must be designed as a “droplet generator”. Droplets are typically generated by creating two liquid phases, one of which is an oil phase and the second of which is typically an aqueous phase. One of the phases is designated by the designer as the continuous phase while the other is the dispersed phase. Droplets are produced by incorporating channels and features in the microfluidic device that create the required hydrodynamic conditions for droplet formation, and the droplet formation process depends strongly on the interaction of flow rate, liquid physical properties and the geometry of the features on the chip(4) . The feature designs are typically classified as “co-flow”, “cross flow” and “flow focusing”. Co-flow is achieved using coaxial microchannels where the continuous phase flows in an outer concentric channel and the dispersed phase flows in the inner channel, both in the same direction. In the crossflow design the dispersed and continuous phases meet at an angle formed by fabricating intersecting microfluidic flow channels. The most common case is the T-junction, where dispersed and continuous phases converge in perpendicular channels. Other microfluidic channel designs for producing droplets via crossflow include the “K-junction” and the “V-junction”. Finally flow focusing designs incorporate a microfluidic contraction region through which coaxial immiscible streams flow and subsequently exit to a single microchannel resulting in the creation of uniform droplets. This method allows for making very small droplets as the formation process is closely related to the size of the narrow contraction.

Droplet Chip Fabrication

Advanced microfabrication technologies enable the flexible design of droplet microfluidic chips such that today a chip design can be rapidly prototyped for applications testing using a variety of techniques such as direct laser and mechanical machining and 3-D printing. Once the design has been finalized, it can be scaled up in volume and scaled down in cost by using microreplication technologies such as hot embossing and microinjection molding. Potomac’s Process & Product Technology team has the expertise to develop scalable microfabrication solutions that result in a fully integrated manufacturing process for producing these chips. We also utilize a variety of advanced surface treatment and chip bonding technologies for modifying material properties and achieving seals that can withstand pressure. Potomac microfluidic and microfabrication experts can even advise you on the design of the microfluidic chip customized for your application and will develop a detailed cost model that will enable you to predict how your unit costs will change as your production requirements increase.

There remains a large window for innovation in the area of droplet microfluidics and laboratories across the globe continue to identify new applications for this technology. Single-cell analysis using droplet microfluidics are likely to evolve together with advances in DNA and

RNA sequencing, amplification and expression technologies.

References

1. Kaminski, T. S., Scheler, O. & Garstecki, P. Droplet microfluidics for microbiology: Techniques, applications and challenges. Lab Chip 16, 2168–2187 (2016).

2. Teh, S. Y., Lin, R., Hung, L. H. & Lee, A. P. Droplet microfluidics. Lab Chip 8, 198–220 (2008).

3. Schütz, S. S., Beneyton, T., Baret, J. C. & Schneider, T. M. Rational design of a high-throughput droplet sorter. Lab Chip 19, 2220–2232 (2019).

4. Shang et al., Chem Rev., 2017, 117, 7964-8040