Theranos has been a nightmare for legitimate medical diagnostics researchers and startups because Lab On a Chip technology was at the center of the failed blood testing startup. Once Silicon Valley and Wall Street darlings, Theranos made headlines not just because the company was forced to shut down but because founder Elizabeth Holmes was convicted for fraud by promising big investors that the company could run a wide range of tests on a single drop of blood.

So….what is Lab On a Chip?

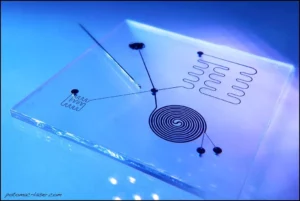

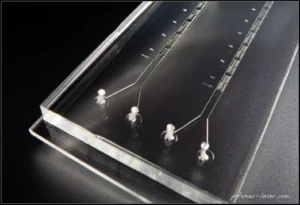

Lab On a Chip is a descriptive term for how microfluidics and other technologies can miniaturize entire chemical or medical fluid analysis test platforms to the size of a computer chip. Consequently, only a small amount of test sample is required for the test, making the procedure to gather blood or other liquids less invasive [read: cheaper!] for patients. Needless to say, squeamish humans, as well as insurance companies, love the concept.

Lab On a Chip offers additional benefits. Obviously, when testing a drop of blood instead of a vial or more, the analysis machine can also be smaller and more economical. And as you would expect, time required to complete Point of Care {POC} diagnostics is faster by orders of magnitude so that accurate treatment plans for patients can be started sooner, leading to exponentially better patient outcomes. Lab On a Chip and its underlying technologies including microfluidics are solid methodologies that offer many solutions in healthcare as well as environmental science including climate change.

Where did Theranos go wrong?

Understanding that Lab On a Chip is a viable technology, begs the question: “why did Theranos fail?”

As explained in The Verge, Stanford dropout Holmes, took the technology too far beyond its current capabilities. Yes, Lab On a Chip can analyze a drop of fluid in minutes instead of days. But not for the vast range of blood tests that Theranos promised. That was Theranos downfall. It could easily perform the tests, but like all microfluidic device POC analysis protocols, only one or maybe two tests could be performed at a time.

What’s real in Lab On a Chip diagnostics?

Happily, there are a large number of companies, big and small, taking Lab On a Chip and microfluidics technology to market. While non-disclosures prevent Potomac from describing some of our most innovative Biotech companies, we can tell you a lot is happening the space with stellar results.

Our prototype to production Lab On a Chip partners are indeed revolutionizing healthcare and environmental science testing but not over-promising like Theranos. Most of the leaders in the field are focusing on a specific application and with just a drop of fluid can change the course of rapid diagnostics for patients and the environment.

Potomac is on the cutting edge of Lab On a Chip as the future of diagnostics with our ability to produce high volume parts economically with our 3D Printing, laser and CNC micro-machining, laser welding, bonding and other state of the art processes. Here’s to more innovative companies using Lab On a Chip without over-promising results!