Reflecting on 2024: One Micron at a Time

As the new year begins, we are proud to reflect on all we accomplished in 2024. Over the past year, we produced components that helped send rockets into space, enabled greater range for electric vehicles, advanced microfluidic devices to fight cancer, and played a pivotal role in ensuring pharmaceutical drugs are safe through ultra precise leak test hole drilling. One micron at a time, we are truly changing the world. With Goodfellow now in the mix, our potential to push the boundaries of microfabrication is stronger than ever.

Moving Forward Together

When Goodfellow acquired Potomac Photonics, one of the major attractions was gaining access to more than 170,000 different materials. Although this was impressive, we have found that the greatest benefit has come from our close collaboration with the Goodfellow technical team. In many cases, customers who arrived with a specific material in mind discovered a more effective alternative for their functional or manufacturing needs. By working together to solve problems, we have delivered strong outcomes for a wide range of applications, from implantable medical devices to space technologies.

Streamlined Communication and Enhanced Presence

We recently launched a new website to make it easier for visitors to explore our capabilities and connect with us directly. This platform reflects our dedication to guiding customers through every stage, from initial inquiries to final production. In addition, we plan to attend several trade shows in the United States and Europe during 2025, where we look forward to meeting prospective partners and clients face to face. These events will allow us to demonstrate how we address microfabrication needs and why high-quality materials lead to the best outcomes.

Market Driven

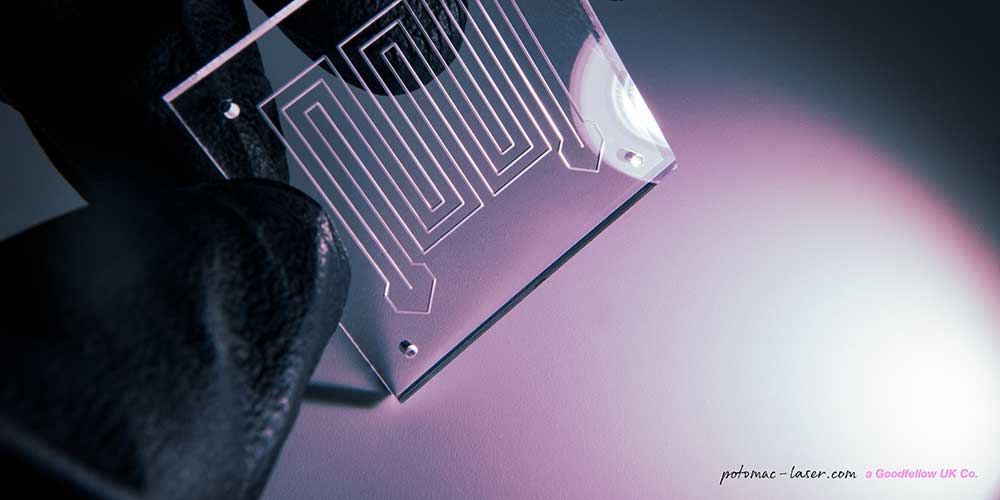

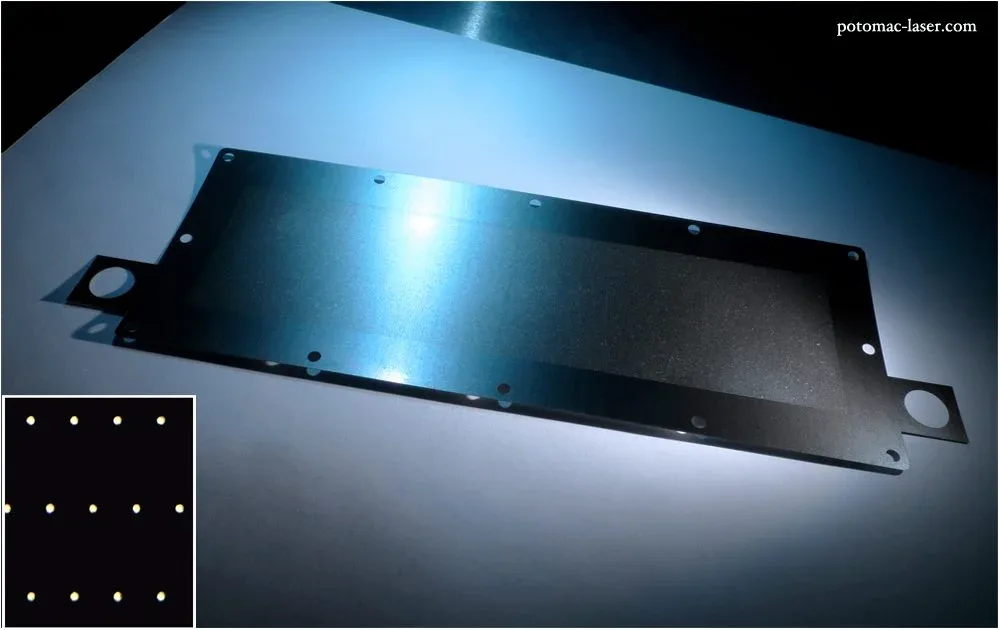

Responding to evolving market needs remains at the core of our mission. Because Goodfellow supplies thin metal foils in significant volumes, we are expanding our capacity to machine features as small as one micron. We are also exploring new materials designed for microfluidic devices, which aligns with our focus on both rapid prototyping and full-scale production. By continually refining our processes and capabilities, we aim to push the limits of microfabrication and deliver ever better solutions to our customers.

Moving into the Future

As we begin 2025, we remain dedicated to meeting our customers’ evolving requirements. We invite anyone interested in learning more about our services or discussing specific projects to visit our newly updated website. Embracing the promise of new beginnings, we look forward to a year of advancement and growth, and we welcome you to join us on this exciting journey.