-

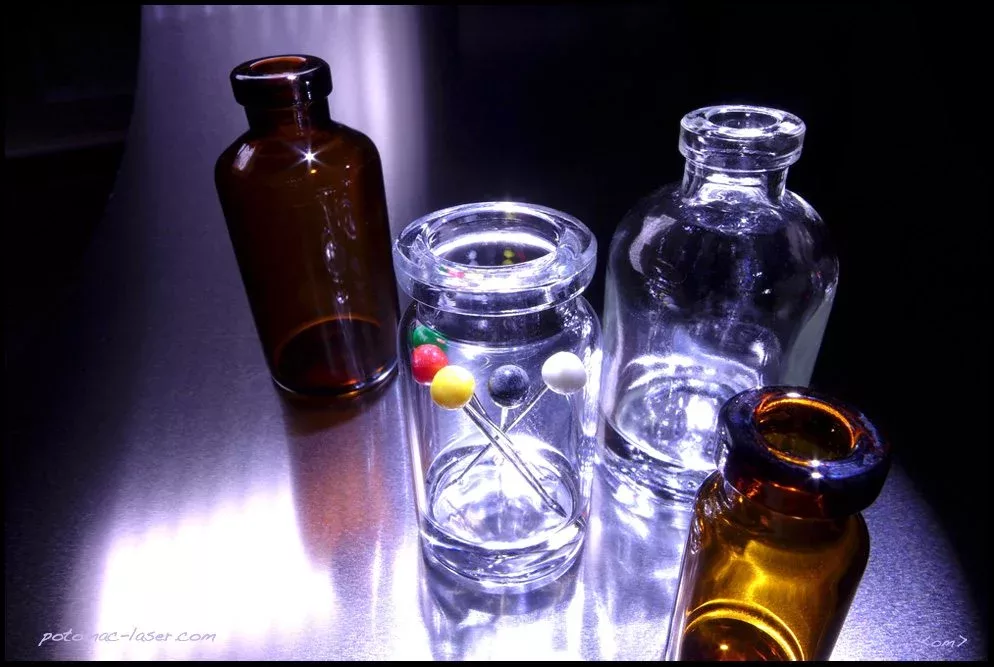

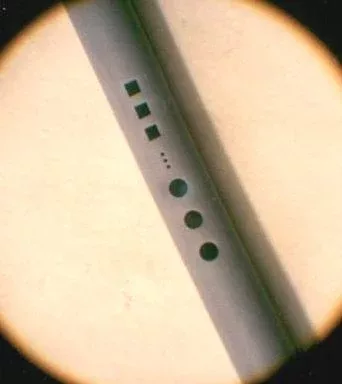

Potomac’s Real-Time Wall Thickness Measurement Produces Consistent Repeatable Laser Drilling for Calibrated Leak Test Holes

Pharmaceutical, medical, and biotech companies are required by the FDA or internal standards to periodically test the vials or ampules for cracks, pinholes and the seal integrity of the cap/closure that can cause potential liquid leakage or contamination. Potomac has…

-

Advanced Manufacturing Trends in 2016 at Potomac Photonics

2016 promises to be another year of explosive innovation in advanced manufacturing. Several emerging applications, especially in the biotech and medical device industries, are driving Potomac Photonics to deliver ever more complex and sophisticated solutions to these new challenges. Here…

-

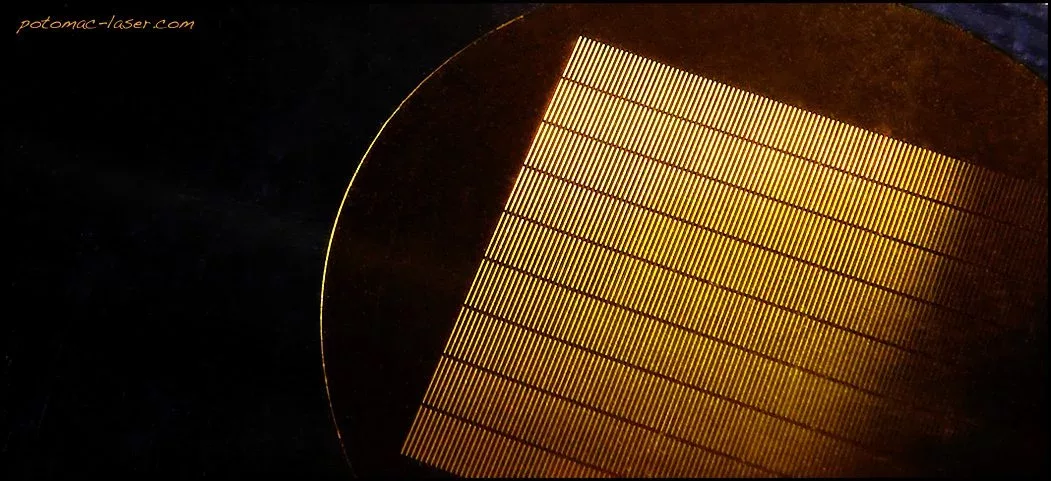

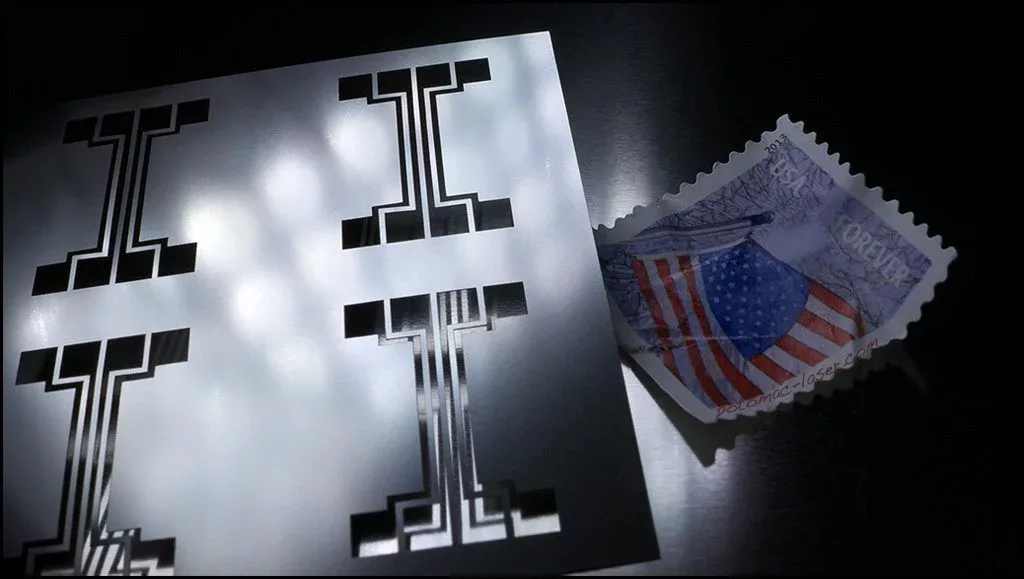

Laser Cutting Silicon Wafers for NIST to Advance Solar Industry Standard

Potomac’s Photonics expertise in laser micromachining fragile materials helps NIST test new solar cells to ensure the solar energy industry’s manufacturing standards. Solar energy is the fastest growing source of energy in the United States and the total install base…

-

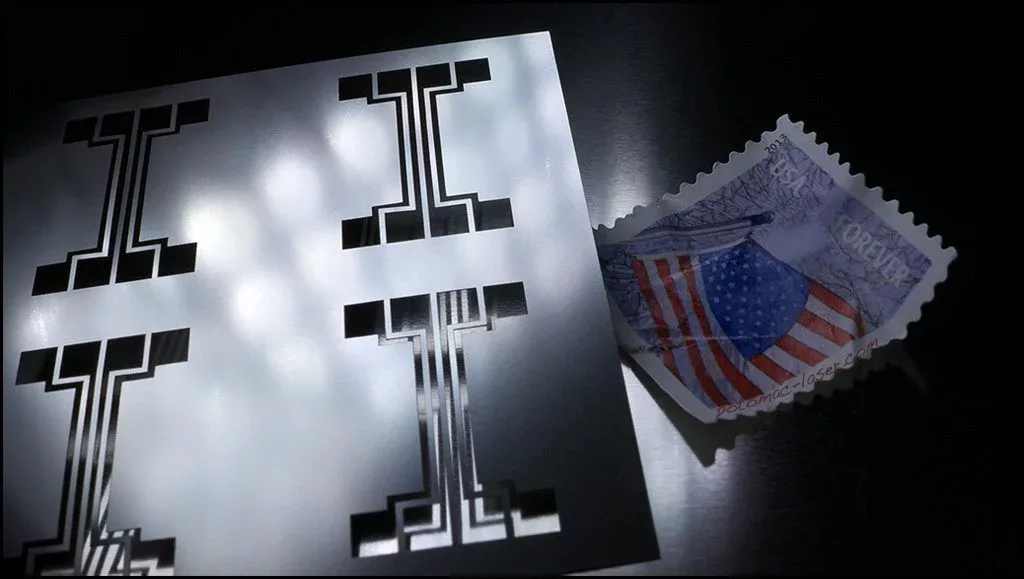

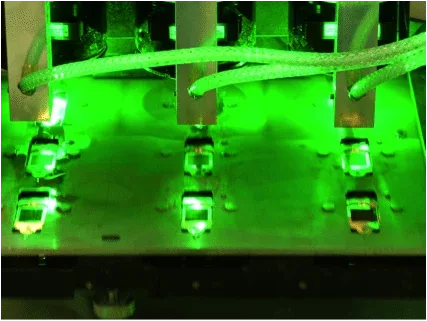

Laser Micromachining Polymer Stencils Help Generate Stem Cell Lines at Stanford’s Cardiovascular Institute

In the Pharmaceutical industry more and more drugs never make it out of the lab to reach the patients that need treatment. Costs are not only high to the companies that have placed big R&D bets to develop novel drugs,…

-

Advanced Manufacturing Job Opportunities Through “Middle-Skill” STEM Education

In recent years there’s been a lot of talk about STEM education. STEM comprises Science – Technology – Engineering – Math and sometimes is called STEAM when Art is added into the mix in order to include the design component. …

-

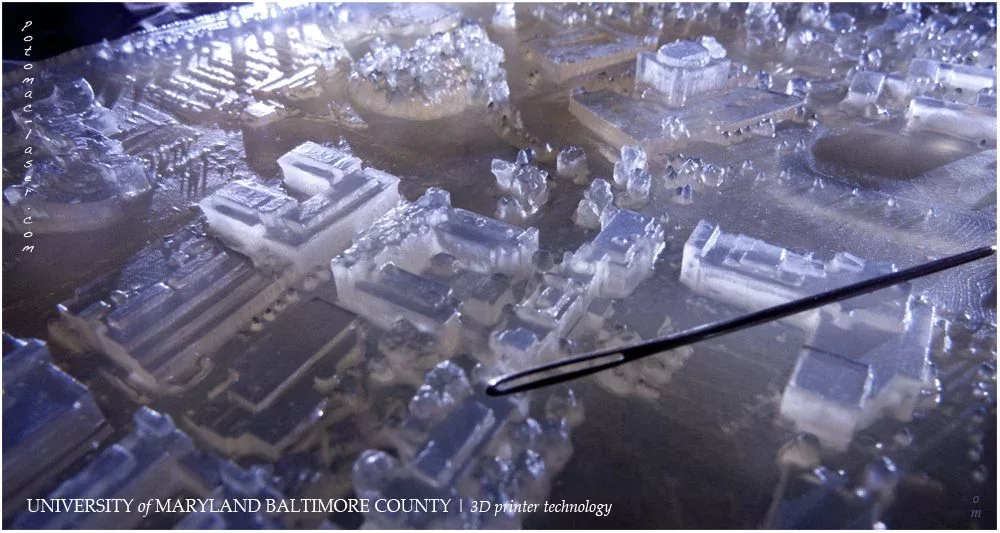

2015: The Year in Review for Potomac

2015 has yet again proven to be a great year at Potomac! We continually strive to be on the cutting edge [pun intended!] of digital fabrication by utilizing the latest tools for laser micromachining, 3D printing, CNC machining, laser marking…

-

When to Choose Laser Micromachining Part 4: Tolerance and Accuracy

Laser micromachining at very small spatial scales demands special attention to precision. Anyone who has ever tried to assemble DIY furniture where holes were slightly off from part to part knows the frustration part variation can cause even for simple…

-

Happy Thanksgiving from Potomac Photonics

The horrors in the news that come to us from around the globe each day challenge us to remember the many things for which the USA is thankful. We do not live in a perfect place but Americans strive to…

-

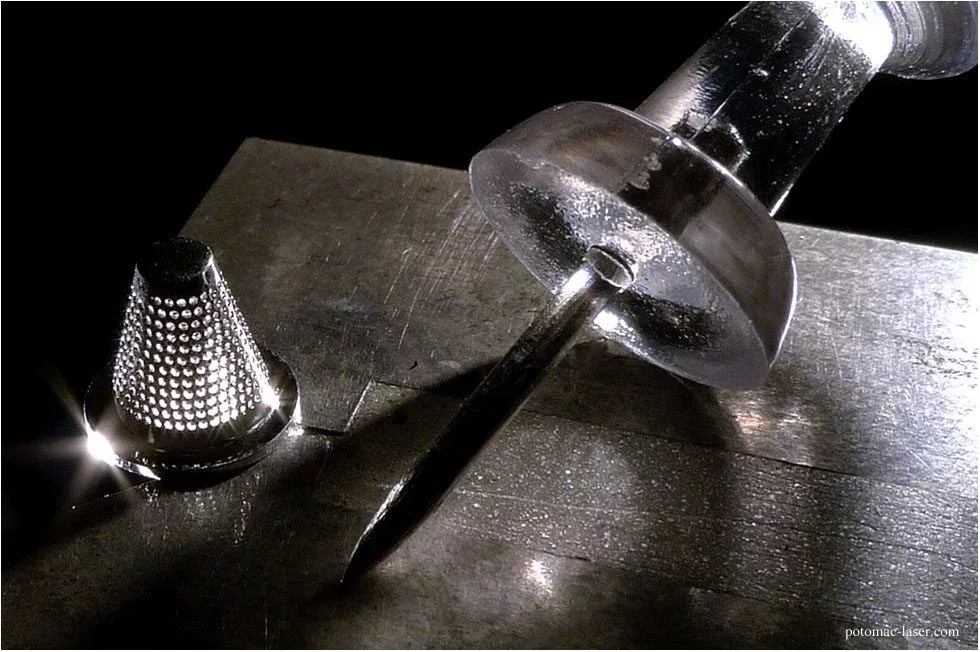

When to Choose Laser Micromachining Part 3: Creating Holes, Cuts and Features with Smooth Surfaces

At Potomac innovation is not just another buzzword. Everyone, from our engineers to the operators on the shop floor, is continually looking for new ways to push the limits of standard laser micromachining technology. Almost perfectly smooth parts have been…

-

When to Choose Laser Micromachining Part 2: Pushing the Limits of Small

When we need to make very small holes, cuts, lines and features laser micromachining is usually the best choice in our digital fabrication toolbox. Lasers that emit light in the ultraviolet region of the spectrum are especially useful in biotech…

-

When to Choose Laser Micromachining Part 1: Material Absorption of Laser Wavelength

All material processing starts, of course, with the material. Laser micromachining is a good option for manufacturing parts since materials absorb light resulting in a physical transformation of the material’s structure. Whether it’s a thermal process as with infrared lasers…

-

When to Choose Laser Micromachining Series

At Potomac we like to say that despite the mainstream media hype, 3D Printing is not yet the Star Trek replicator. The same is true for all the technologies we use to make products for our customers. From prototype to…