-

New Potomac R&D Notebook Sheds Light on Internal Programs for Advanced Manufacturing Processes

Advanced manufacturing services involve more than just feeding CAD files into a 3D Printer, laser micromachining workstation or micro CNC machine. To best service our customers in the biotech, medical device and microfluidics industries, Potomac has had to stay at…

-

Helping the New Jersey Institute of Technology with New Microfluidics Techniques for Analysis and Personalized Medicine

Microfluidics is a fast-moving field on many levels, and we’re seeing new, innovative techniques being developed to fabricate devices that will impact chemical analysis, personalized medicine and pharmaceuticals. Dr. Sagnik Basuray’s group in the Department of Chemical, Biological and Pharmaceutical…

-

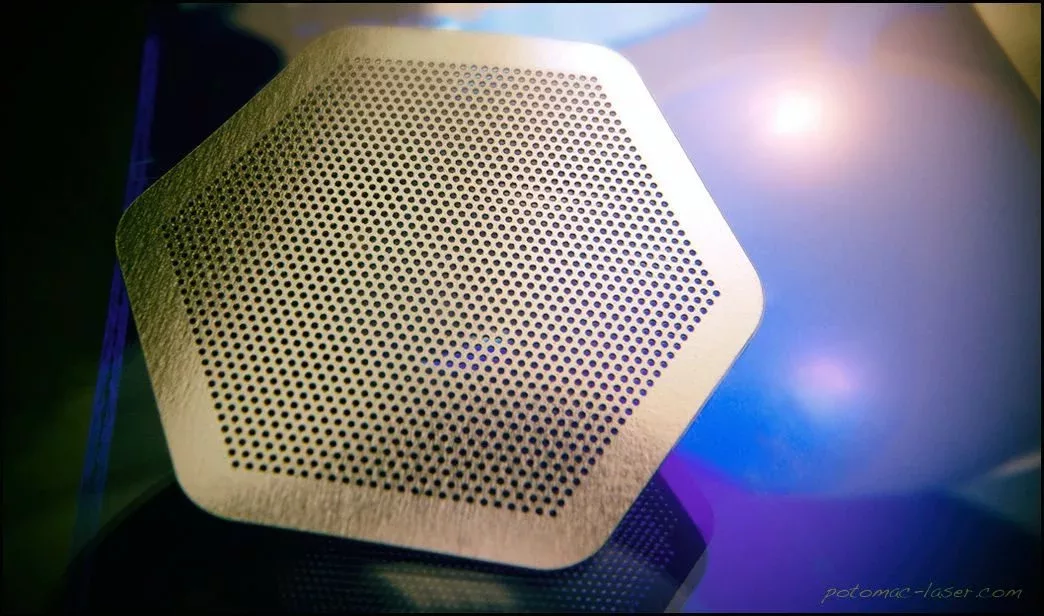

Precision Laser Micromachining to Help Launch a Polytechnique Montréal CubeSat into Space

At Potomac we’re used to seeing some of the most interesting – and challenging – miniaturization projects on the planet. Recently we helped a Canadian university group miniaturizing for a space application. Polytechnique Montréal is competing in the Canadian Satellite…

-

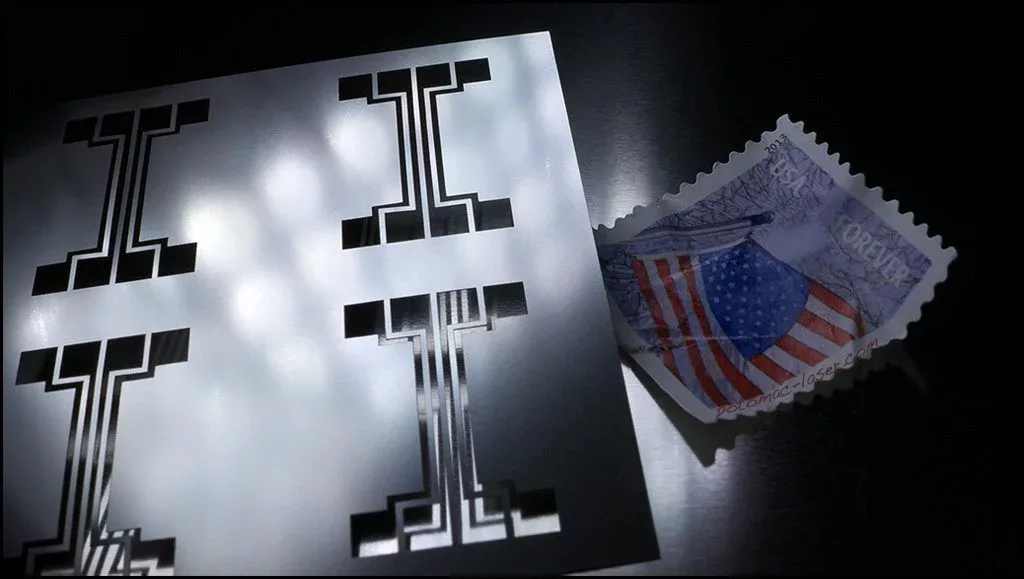

IR Laser Patterning of ITO to Help Basic Physics Research at MIT and Harvard

Patterning Transparent Conductive Oxide [TCO] layers on substrates such as glass or plastic is a familiar laser micromachining application at Potomac. We’ve developed innovative ways to pattern the TCO layer without damaging the underlying substrate. But we usually see TCO’s…

-

Potomac Photonics in the News with Advanced Manufacturing for Biotech and Medical Device Industries

Recently Potomac Photonics has been in the news bringing perspective to advanced manufacturing for the biotech and medical device markets. Symposium on Bio-medical Additive Manufacturing On March 4, Mike Adelstein was part of a panel discussion at the RAMPMD Symposium…

-

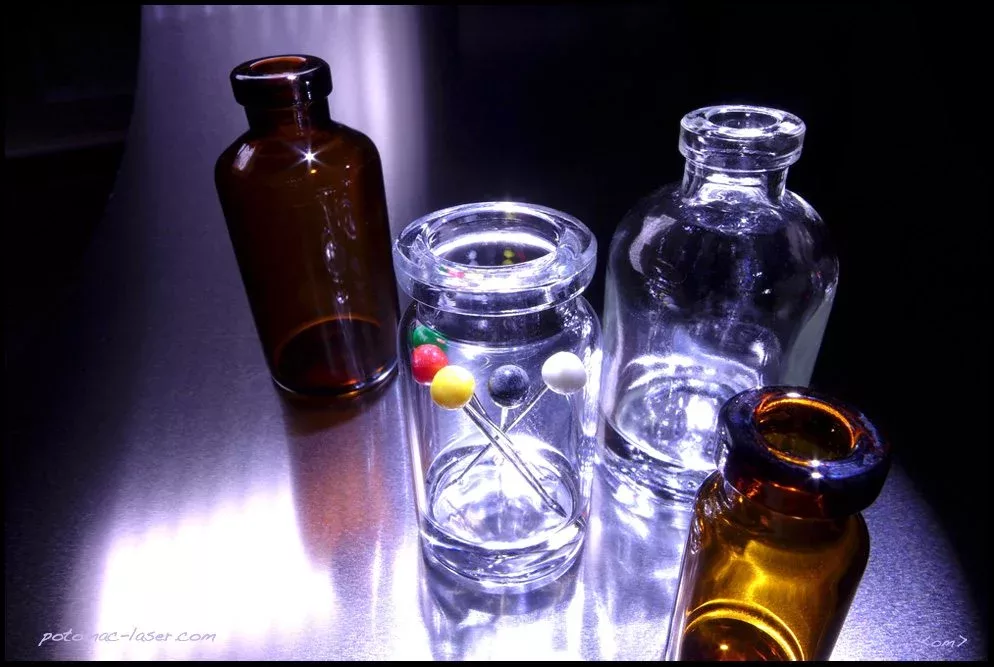

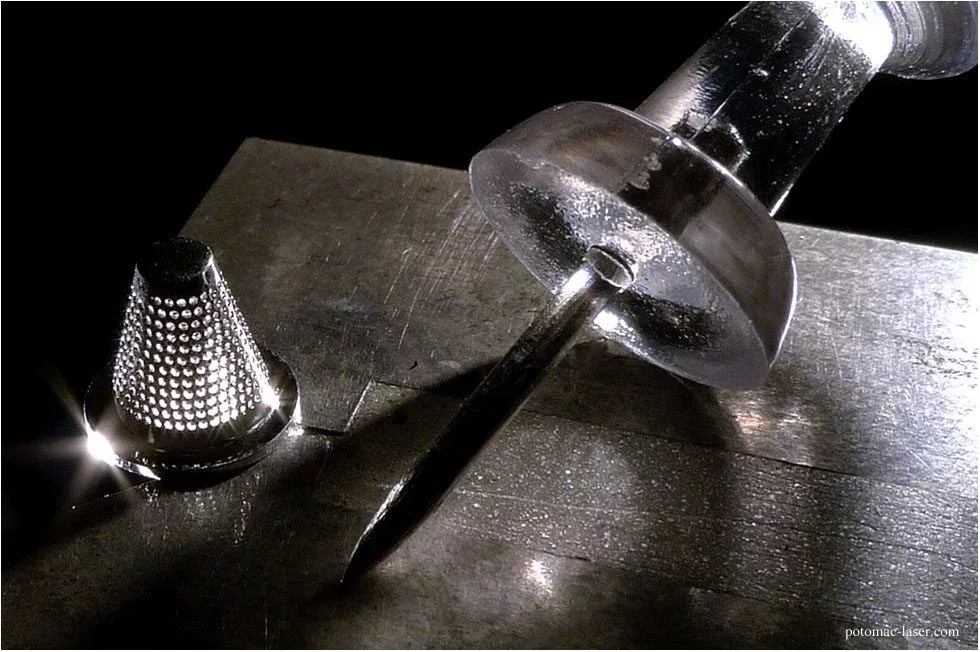

Potomac’s Real-Time Wall Thickness Measurement Produces Consistent Repeatable Laser Drilling for Calibrated Leak Test Holes

Pharmaceutical, medical, and biotech companies are required by the FDA or internal standards to periodically test the vials or ampules for cracks, pinholes and the seal integrity of the cap/closure that can cause potential liquid leakage or contamination. Potomac has…

-

Advanced Manufacturing Trends in 2016 at Potomac Photonics

2016 promises to be another year of explosive innovation in advanced manufacturing. Several emerging applications, especially in the biotech and medical device industries, are driving Potomac Photonics to deliver ever more complex and sophisticated solutions to these new challenges. Here…

-

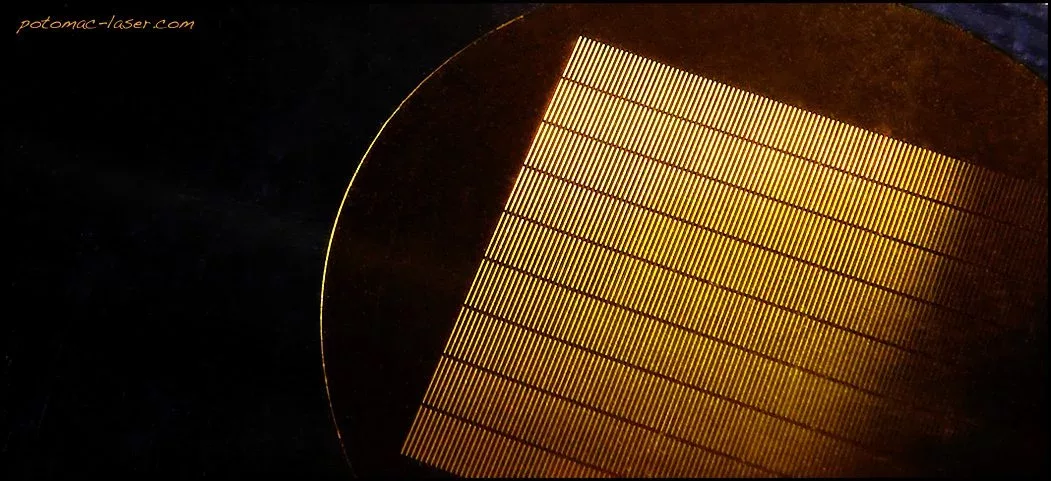

Laser Cutting Silicon Wafers for NIST to Advance Solar Industry Standard

Potomac’s Photonics expertise in laser micromachining fragile materials helps NIST test new solar cells to ensure the solar energy industry’s manufacturing standards. Solar energy is the fastest growing source of energy in the United States and the total install base…

-

Laser Micromachining Polymer Stencils Help Generate Stem Cell Lines at Stanford’s Cardiovascular Institute

In the Pharmaceutical industry more and more drugs never make it out of the lab to reach the patients that need treatment. Costs are not only high to the companies that have placed big R&D bets to develop novel drugs,…

-

Advanced Manufacturing Job Opportunities Through “Middle-Skill” STEM Education

In recent years there’s been a lot of talk about STEM education. STEM comprises Science – Technology – Engineering – Math and sometimes is called STEAM when Art is added into the mix in order to include the design component. …

-

2015: The Year in Review for Potomac

2015 has yet again proven to be a great year at Potomac! We continually strive to be on the cutting edge [pun intended!] of digital fabrication by utilizing the latest tools for laser micromachining, 3D printing, CNC machining, laser marking…

-

When to Choose Laser Micromachining Part 4: Tolerance and Accuracy

Laser micromachining at very small spatial scales demands special attention to precision. Anyone who has ever tried to assemble DIY furniture where holes were slightly off from part to part knows the frustration part variation can cause even for simple…