-

Potomac’s High Precision Laser Micromachining Advances New Energy-Harvesting Technique at UMBC

Anyone who has found themselves without the power cord for their laptop, iPad or smart phone knows the frustration of living in a “connected” world. Energy-harvesting is one of the research areas that would cut the cord, so to speak,…

-

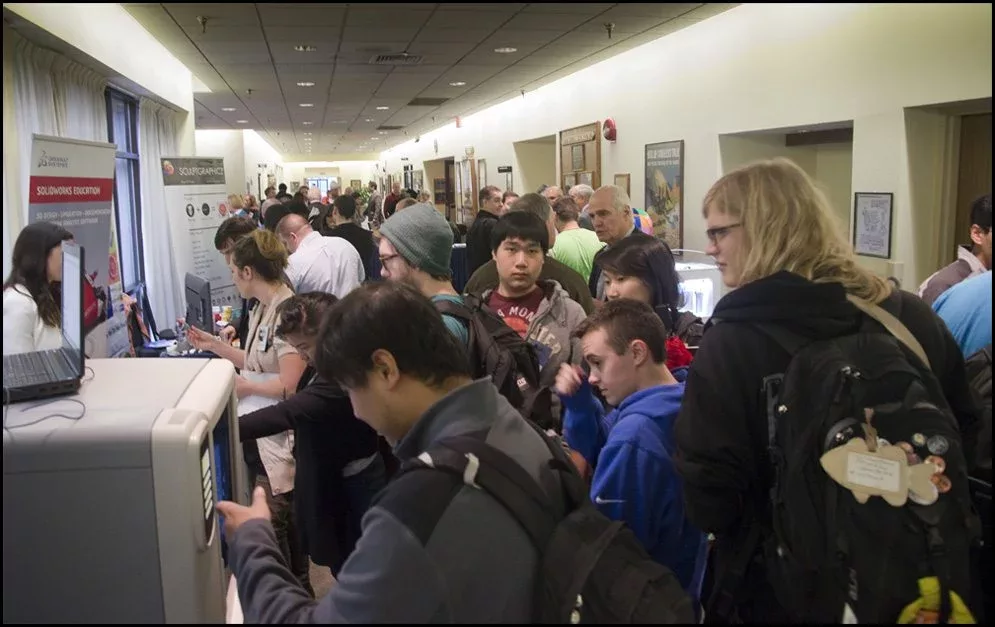

Potomac Gives Back to Community Through Education at DigiFabCon

Thanksgiving is a time when we think about giving back to the community in thanks for our own success and good fortune. Recently, Potomac had an opportunity to share our expertise on the powerful use of digital fabrication in diverse…

-

Laser Micromachining Helps Oregon State Improve Equipment for Research in BioPhysics, Astrophysics and Materials Science

Advanced research in basic science is continually pushing the limits of commercially available chemical analysis equipment. Such is the case for the Kong group at Oregon State University whose physical chemistry work involves studying the basic structure of materials on…

-

Focus on Biotech: Leak Detection Calibration Hole Drilling

Potomac Expands its Leak Detection Hole Drilling Capabilities Every pharmaceutical, food, and nutrition products manufacturer is faced with the challenge of making sure their products meet the highest quality standards. Container integrity is one of the major concerns when it…

-

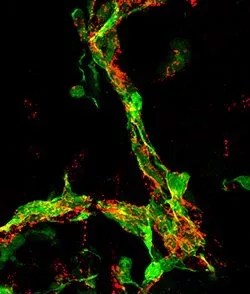

Maryland BioTech Feature: Stem Cell Center Translates Basic Research to Innovative Approaches to Cancer Treatment

Potomac is fortunate to be located in Maryland, which is one of the nation’s leading areas for BioTech research and development. With highly regarded medical schools at the University of Maryland and Johns Hopkins in Baltimore, and the National Institutes…

-

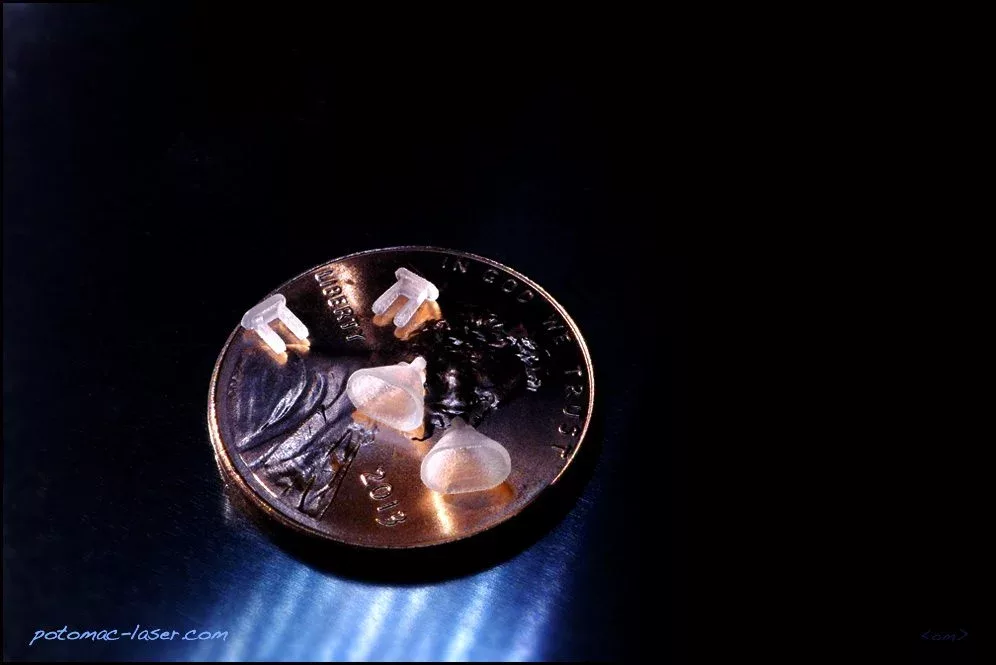

Micro 3D Printing Middle Ear Prosthesis To Bring Music to the Ears of Hearing Loss Sufferers

3D Printing is frequently in the news as a process for manufacturing prosthesis to replace lost limbs. And it’s an obvious choice when additive manufacturing is combined with 3D Scanning to easily custom fit a prosthetic to a patient’s unique…

-

If you can’t take the heat, get behind the heat shield… Potomac’s latest project for NASA

Part II of a series of blog posts focused on Innovative Manufacturing…. Micro marking is more than just being able to focus a laser to a small spot size. Accurate placement of marks on small components with high precision requires…

-

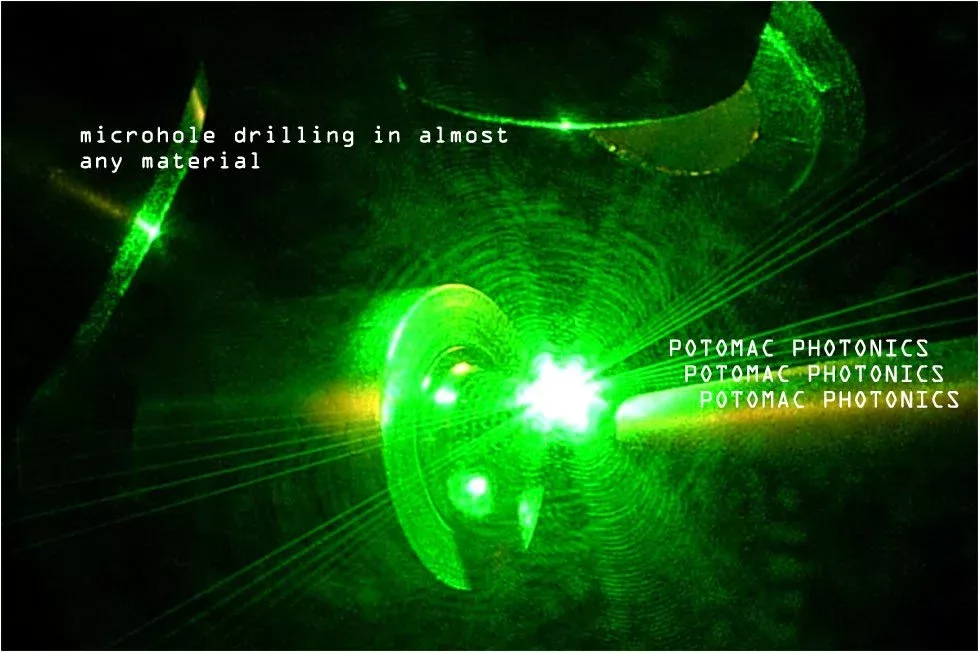

Laser Micromachining Tools: Seeing the Light!

Part I of a series of blogs posts focused on Innovative Manufacturing Technologies As the trend toward miniaturization of devices accelerates, finding the right tool for the job is becoming more challenging. Options that initially seem promising often fall short…

-

Potomac’s New ISO 9001:2008 & 13485:2003 Certification Renewal Verifies Our Customer-Centric Philosophy

Recently, Potomac passed both internal and external audits to become re-certified in the ISO international standards program. From its inception Potomac has worked from a customer-centric philosophy and our first ISO certification in 2006 codified our commitment to quality. Going…

-

UMBC Art Student Creates “Pathway to the Future” Mural for New Potomac bwtech@UMBC Research and Technology Park Facility

Potomac Photonics’ new location at the bwtech@UMBC Research and Technology Park is giving us great opportunities for collaboration with the University of Maryland, Baltimore County. While we are already involved in science and engineering projects, we recently had a wonderful…

-

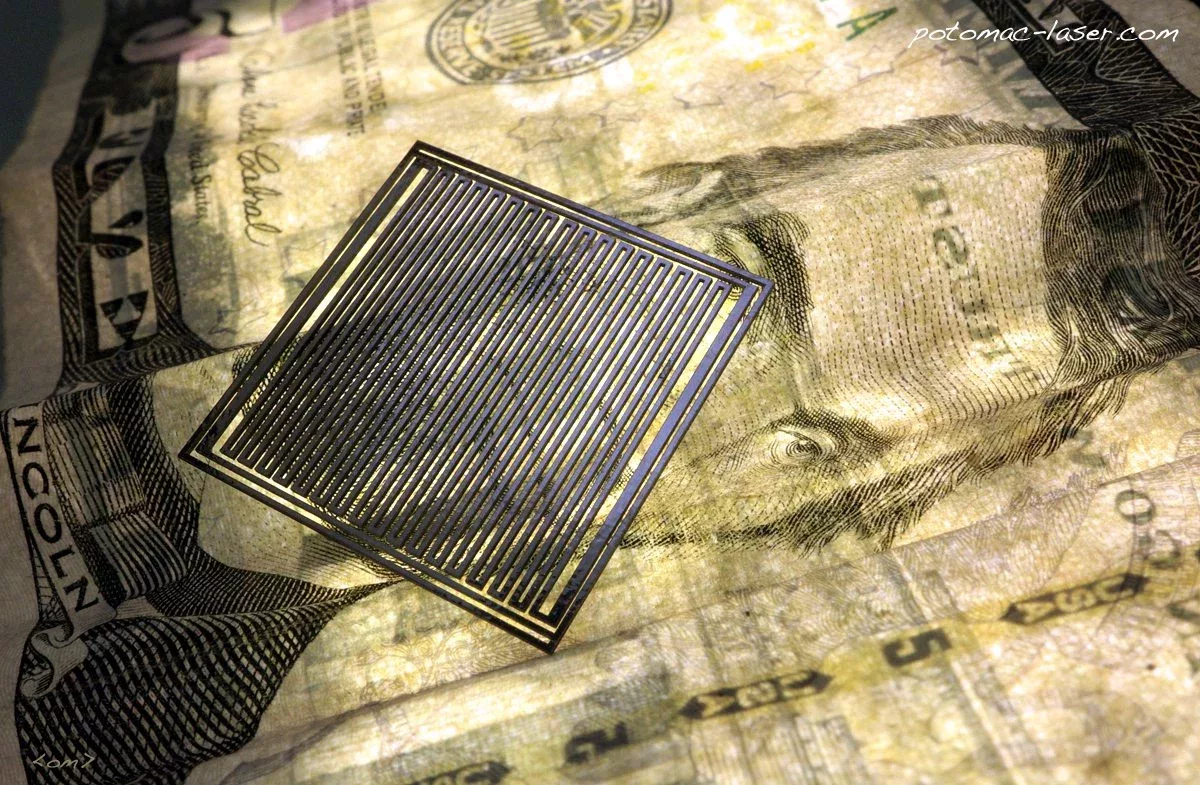

Helping Oregon State University Improve a Radiation Detector with Laser Micromachining Expertise

At Potomac, we often talk about selecting the right tool from our factory floor for the job at hand. A recent opportunity to manufacture a shadow mask for a radiation detection project at Oregon State University allowed us to solve…

-

Lasers: Key Tools for Micromaching

Many components used in modern products are getting smaller. Over the last three decades, features in integrated-circuit technology have been reduced in size by approximately two orders of magnitude, and micromotors as small as a human hair have been fabricated…