-

Potomac, NASA and Small Parts….

Potomac Photonics has been collaborating with our friends at NASA for years. In fact, it was a set of Small Business Innovation Research contracts with NASA’s Marshall Space Flight Center back in the mid-1990s that was instrumental in putting our…

-

Remembering Laser Inventor Charles Townes and His Impact on Potomac’s Micromachining Work

Last week the laser community was saddened to learn of the death of Charles Townes, one of the inventors of the laser. Light Amplification by Stimulated Emission of Radiation [LASER] devices are such a part of 21st century life that…

-

Potomac’s 2015 Resolution: To Build upon Digital Fabrication Successes of 2014

2014 was a year of many successes for Potomac. First and foremost, we moved to the bwtech@umbc research and development campus near Baltimore. Moving a functioning company after over 30 years on the DC Beltway was no small feat, but…

-

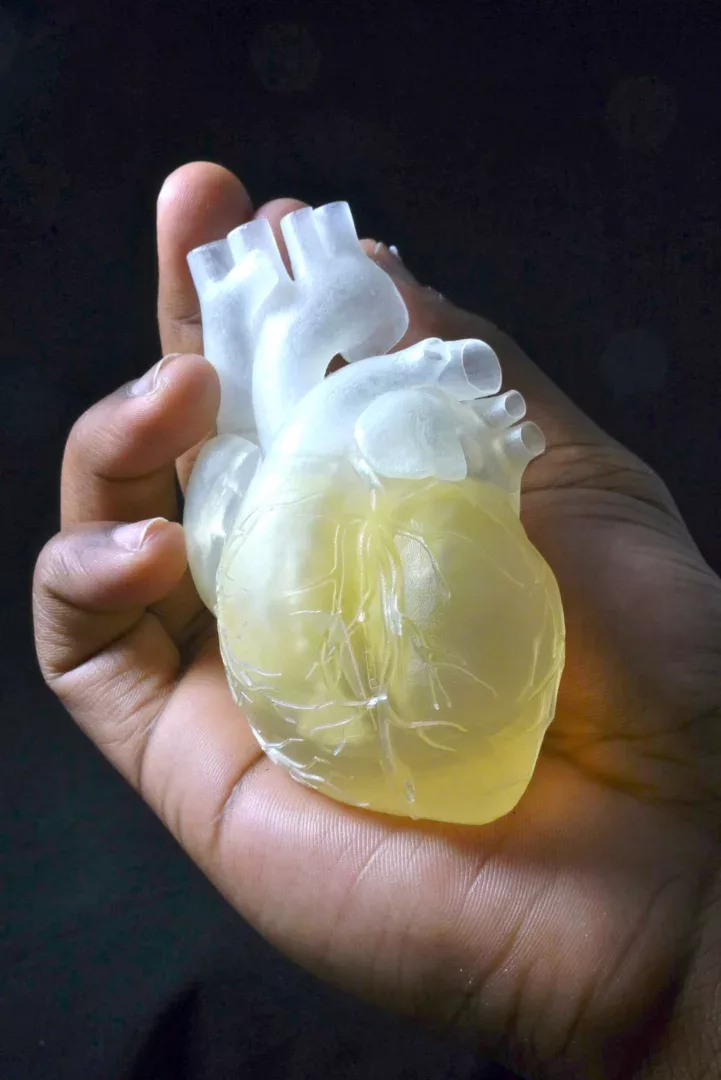

Rapid Prototyping Micro Fixtures for Cardiovascular Biomechanics Research at the University of Texas, Austin

Computer simulations are powerful tools for development of new medical devices and treatments. At the Center for Cardiovascular Simulation (CCS) at the University of Texas, Austin, Dr. Michael Sacks’ group is working to provide advanced cardiovascular simulations in order for…

-

Potomac’s High Precision Laser Micromachining Advances New Energy-Harvesting Technique at UMBC

Anyone who has found themselves without the power cord for their laptop, iPad or smart phone knows the frustration of living in a “connected” world. Energy-harvesting is one of the research areas that would cut the cord, so to speak,…

-

Potomac Gives Back to Community Through Education at DigiFabCon

Thanksgiving is a time when we think about giving back to the community in thanks for our own success and good fortune. Recently, Potomac had an opportunity to share our expertise on the powerful use of digital fabrication in diverse…

-

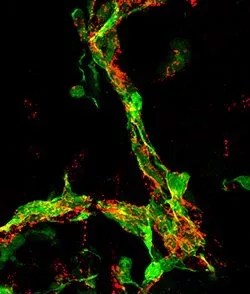

Maryland BioTech Feature: Stem Cell Center Translates Basic Research to Innovative Approaches to Cancer Treatment

Potomac is fortunate to be located in Maryland, which is one of the nation’s leading areas for BioTech research and development. With highly regarded medical schools at the University of Maryland and Johns Hopkins in Baltimore, and the National Institutes…

-

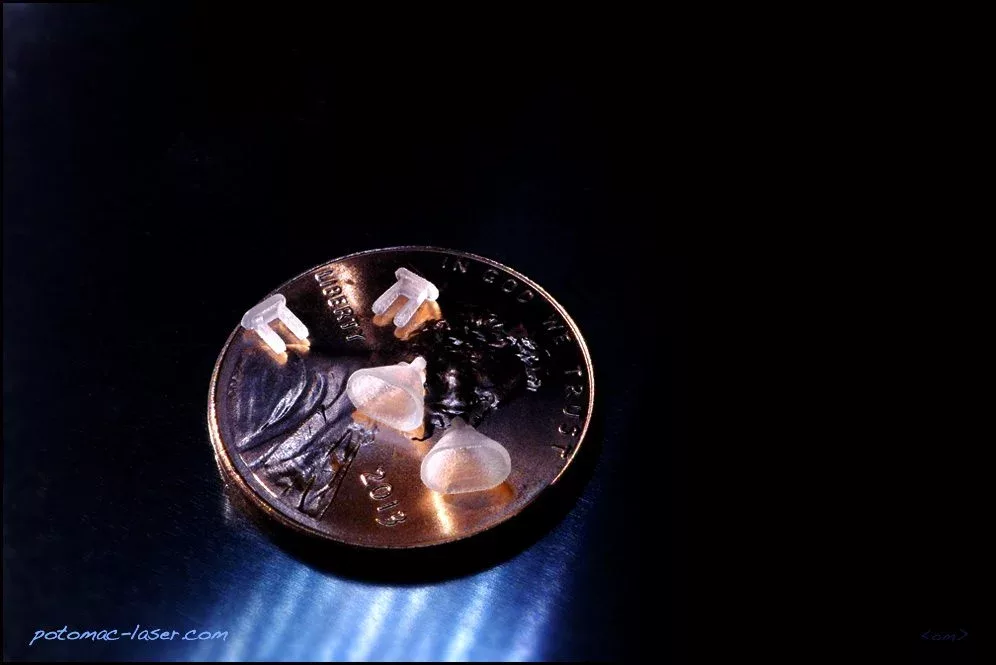

Micro 3D Printing Middle Ear Prosthesis To Bring Music to the Ears of Hearing Loss Sufferers

3D Printing is frequently in the news as a process for manufacturing prosthesis to replace lost limbs. And it’s an obvious choice when additive manufacturing is combined with 3D Scanning to easily custom fit a prosthetic to a patient’s unique…