Microfluidics has been around for decades and in the last few years has come into its own as a viable technology for point of care diagnostics, cancer research, personalized medicine and environmental testing. When Potomac first started working with researchers in the new field, material choices were limited. But the processes that drove material options have evolved giving researchers a wide array of excellent materials for building devices.

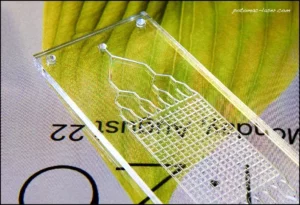

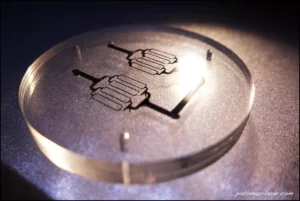

Silicon and then glass were the only material choices when microfluidic chips were solely created through photolithographic manufacturing methods. As new technologies like high precision laser and CNC micromachining, molding and hot embossing developed, devices could now be manufactured in low-cost plastics. Simultaneously, high quality plastics arrived on the market that rivaled glass in performance but were far more economical.

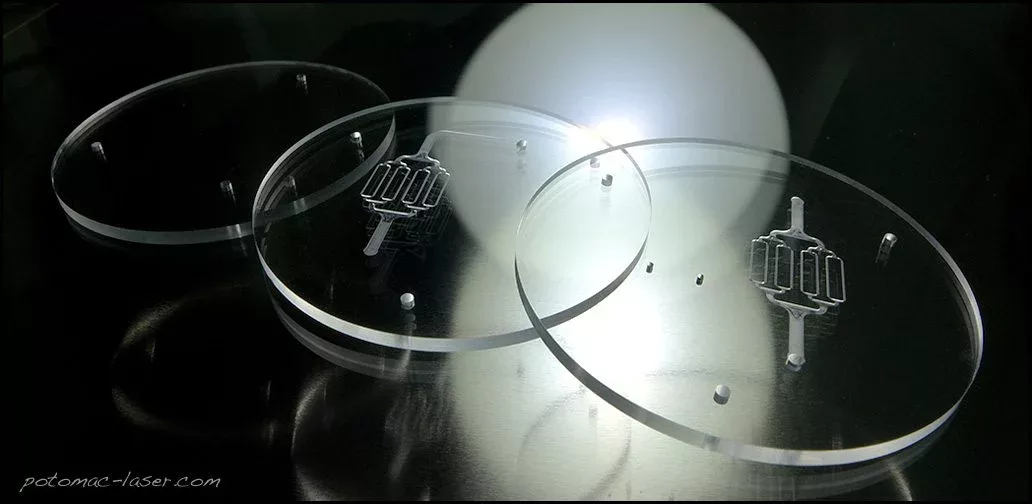

POLY-METHYL METHACRYLATE (PMMA) and Cyclic olefin copolymers (COC) are two excellent polymers that create microfluidic devices with light transmission qualities approaching glass. In addition to being inexpensive to purchase, processing costs are a fraction of that for glass.

For complete details about exciting new developments in utilizing polymers to prototype and manufacture microfluidic chips, go to our website’s glass versus polymer page.