In recent years pharmaceutical and medical device processors have increasingly relied upon packaging quality to improve product shelf life and efficacy. Whenever there is any sort of physical breach of the packaging structure, the product integrity is compromised, reducing yields and possibly safety. The resulting costs associated with poor quality in turn increase a supplier’s manufacturing expense, negatively impacting all corporate efforts at cost containment. Poor product quality ultimately shows up in the bottom line.

While package leak testing is now new, next generation leak detection technologies have entered the marketplace that generate much more accurate results when compared with traditional leak testing. For example, a recent industry test study showed that new laser scanning equipment is able to detect 100% of 10 micron-sized holes versus 50% for older blue dye testing procedures.

These more sophisticated testing equipment and methodologies then lead to a new requirement that leak test system validation and calibration samples provide tighter small hole drilling capabilities for measuring results. Potomac laser micromachining technology is one of the few ways to drill holes with adequate size and accuracy to fully put the new testing equipment through its paces.

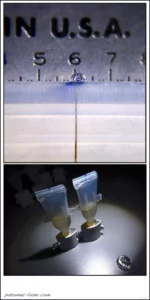

Potomac can laser drill holes as small as one micron with highly accurate placement in a wide range of packaging materials including organic polymers and other plastics, glass, metals and ceramics. Laser hole drilling is successful in rounded as well as flat packaging such as vials, ampoules, pouches, bottles, foil and blister packs, and metal containers. Small hole drilling in leak test samples is an important aspect of a complete package quality control program.

At Potomac we have our own robust, internal quality control program and we have achieved ISO 9001:2008 and ISO 13485:2013 certifications. A Certificate of Conformance and Quality Data Sheet is included with each Leak Test Hole Drilling Order verifying results for your testing program.

When your leak test system needs smaller hole drilling in packaging than in the past, let Potomac fabricate test samples that will bring your quality control program to new heights, along with increasing your bottom line.