-

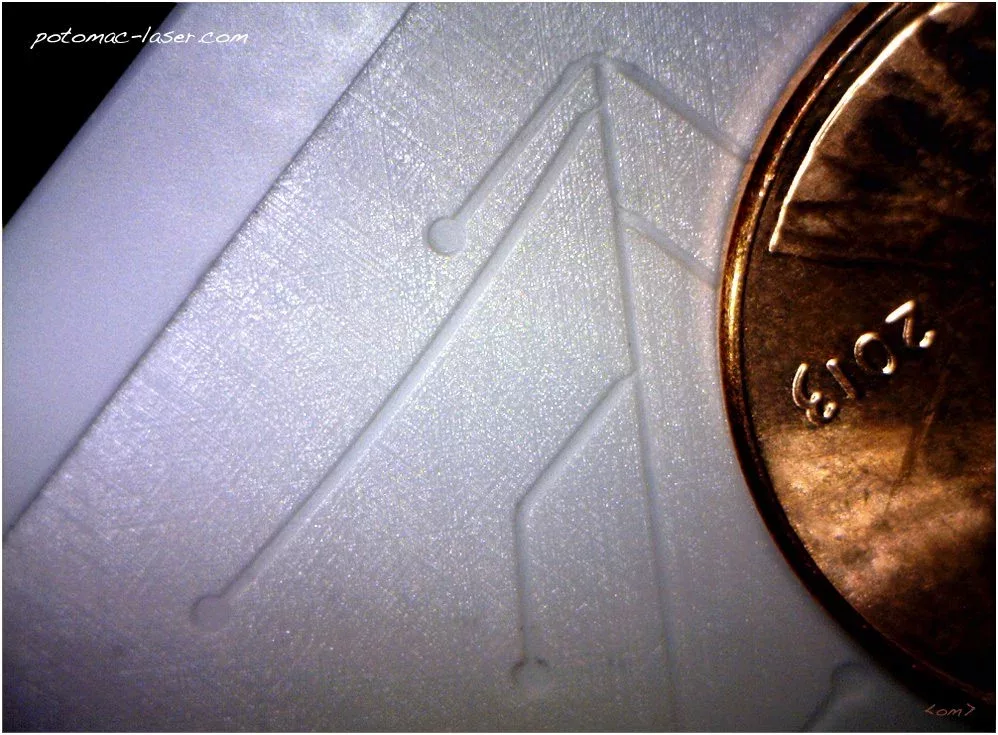

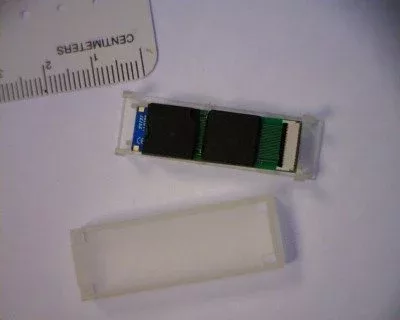

Micro Notes: Microfludic Channels in Polystyrene

VIEW DETAILS: Micro Notes: Microfludic Channels in PolystyreneWe recently completed a project in which a customer required very precise micro channels in Polystyrene. Polystyrene can be a difficult material to laser machine, as the thermal effects of the process are often greater than are seen with other…

-

When to Choose 3D Printing Part 2: Mass Customization or Frequent Design Changes

VIEW DETAILS: When to Choose 3D Printing Part 2: Mass Customization or Frequent Design ChangesInherent to Digital Fabrication is the ability to change a design quickly and easily in a Computer Aided Design [CAD] file. Need to modify a design for a part to fit a new assembly? Need to custom fit each customer? …

-

When to Choose 3D Printing Part 1: Parts with Complex Geometries

VIEW DETAILS: When to Choose 3D Printing Part 1: Parts with Complex GeometriesOne of the great advantages of Additive Manufacturing [AM] is the ability to lay down material in ways that would be impossible by conventional techniques. Digital Fabrication uses a Computer Aided Design [CAD] file to instruct a machine tool where…

-

When to Choose 3D Printing For the Right Digital Fabrication Job

VIEW DETAILS: When to Choose 3D Printing For the Right Digital Fabrication JobThe rise of 3D Printing to the forefront of manufacturing in recent years has projected that the Additive Manufacturing technology will take over all processes on the factory floor. While we use our advanced high resolution 3D Systems Corporation ProJet…

-

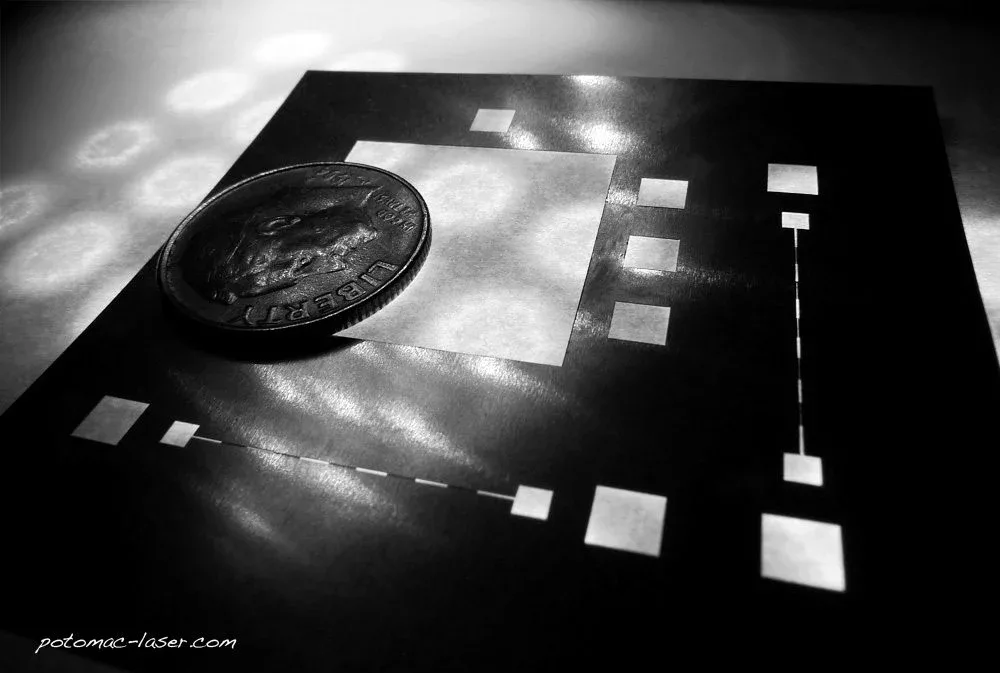

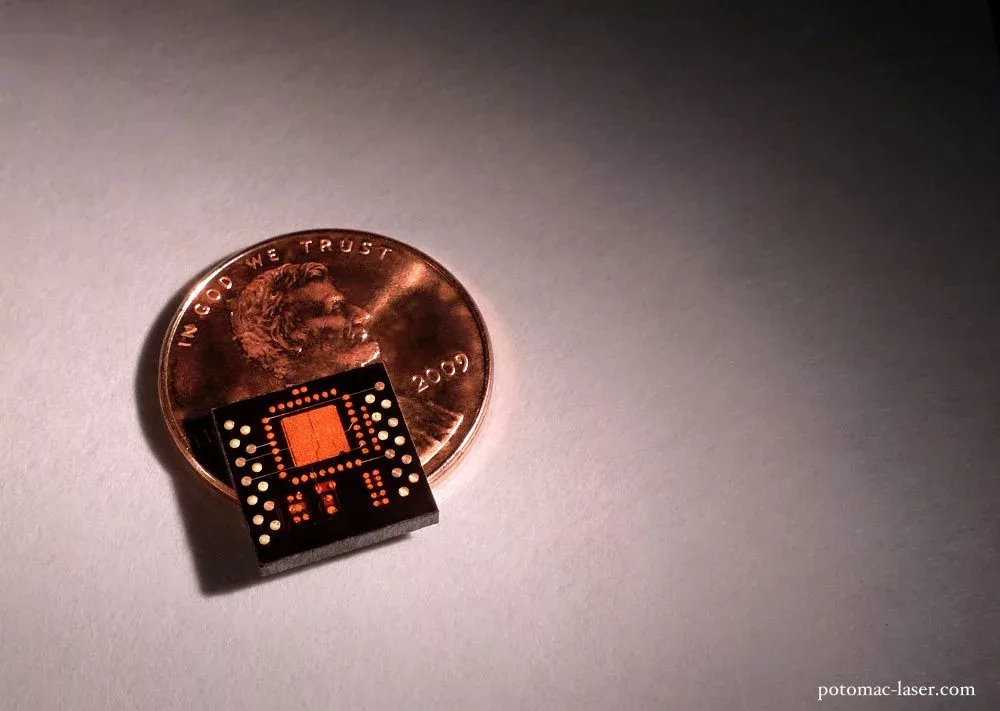

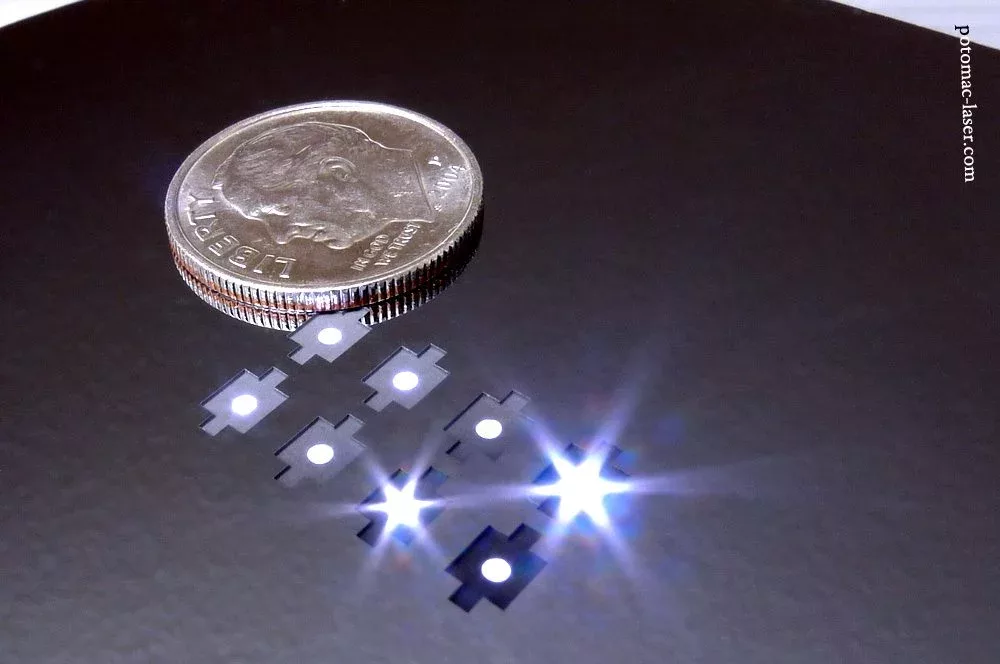

Potomac Photonics Makes Shadow Masks For MIT Work on Energy Efficient Computing

VIEW DETAILS: Potomac Photonics Makes Shadow Masks For MIT Work on Energy Efficient ComputingJuly 25, 2013; Lanham, MD: Potomac Photonics, a leader in micro hole drilling technology, has recently completed a project making shadow masks for work leading to energy efficient computing at the Massachusetts Institute of Technology in Cambridge, MA. With ever increasing energy…

-

Potomac Photonics Creates QR Code Method to Link Donors to Cal Ripken, Sr. Foundation

VIEW DETAILS: Potomac Photonics Creates QR Code Method to Link Donors to Cal Ripken, Sr. FoundationJuly 10, 2013, Lanham, MD: Digital Fabrication industry leader Potomac Photonics, Inc. has developed a new QR Code method to tie donors to the non-profit Cal Ripken, Sr. Foundation. Using the power of laser marking technology, Potomac created a powerful tool for marketing…

-

Potomac Photonics Develops New High Speed Micro Hole Drilling Process

VIEW DETAILS: Potomac Photonics Develops New High Speed Micro Hole Drilling ProcessHigh speed micro hole drilling process increases throughput, accuracy and aspect ratio for work in metals such as stainless steel, copper, titanium among others. June 27, 2013, Lanham, MD: Building upon 30 years of innovation in manufacturing, precision micromachining firm…

-

Micro-hole Drilling Experts Potomac Photonics Featured in PCB Magazine

VIEW DETAILS: Micro-hole Drilling Experts Potomac Photonics Featured in PCB MagazineThe article describes new techniques that combine laser fabrication with conductive nanoparticle materials, allowing further miniaturization of electronic devices among other benefits. Lanham, MD, May 22, 2013 – Micro-hole drilling expert Potomac Photonics was recently featured in PCB Magazine’s May issue…

-

Cost of Micromachining

VIEW DETAILS: Cost of MicromachiningOur goal is to inspire and enable innovation and new technology by providing services with accessibility and pricing that will revolutionize manufacturing on a global scale. In these economic challenging times, Potomac Photonics stands ready to provide you with the…