-

Happy Thanksgiving from Potomac Photonics

VIEW DETAILS: Happy Thanksgiving from Potomac PhotonicsThe horrors in the news that come to us from around the globe each day challenge us to remember the many things for which the USA is thankful. We do not live in a perfect place but Americans strive to…

-

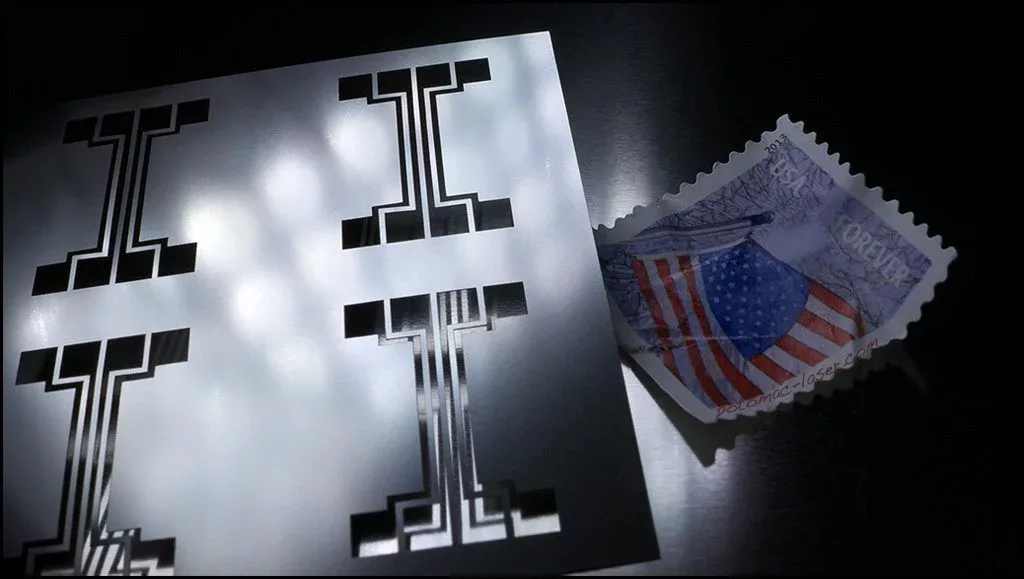

When to Choose Laser Micromachining Part 3: Creating Holes, Cuts and Features with Smooth Surfaces

VIEW DETAILS: When to Choose Laser Micromachining Part 3: Creating Holes, Cuts and Features with Smooth SurfacesAt Potomac innovation is not just another buzzword. Everyone, from our engineers to the operators on the shop floor, is continually looking for new ways to push the limits of standard laser micromachining technology. Almost perfectly smooth parts have been…

-

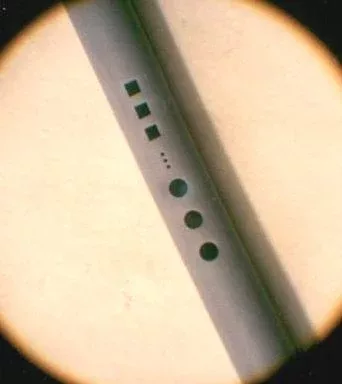

When to Choose Laser Micromachining Part 2: Pushing the Limits of Small

VIEW DETAILS: When to Choose Laser Micromachining Part 2: Pushing the Limits of SmallWhen we need to make very small holes, cuts, lines and features laser micromachining is usually the best choice in our digital fabrication toolbox. Lasers that emit light in the ultraviolet region of the spectrum are especially useful in biotech…

-

When to Choose Laser Micromachining Part 1: Material Absorption of Laser Wavelength

VIEW DETAILS: When to Choose Laser Micromachining Part 1: Material Absorption of Laser WavelengthAll material processing starts, of course, with the material. Laser micromachining is a good option for manufacturing parts since materials absorb light resulting in a physical transformation of the material’s structure. Whether it’s a thermal process as with infrared lasers…

-

When to Choose Laser Micromachining Series

VIEW DETAILS: When to Choose Laser Micromachining SeriesAt Potomac we like to say that despite the mainstream media hype, 3D Printing is not yet the Star Trek replicator. The same is true for all the technologies we use to make products for our customers. From prototype to…

-

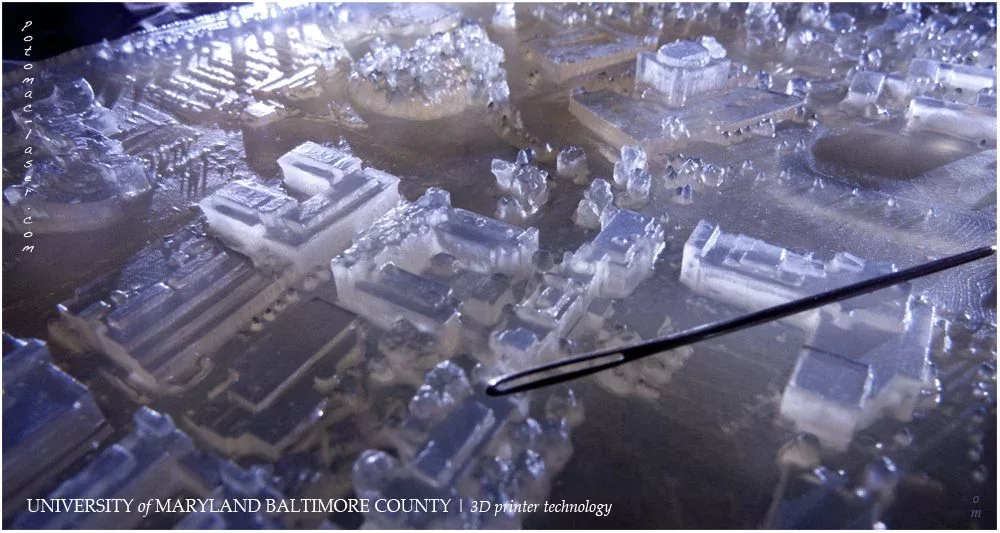

3D Printing, the Orioles, and Making Wishes Come True

VIEW DETAILS: 3D Printing, the Orioles, and Making Wishes Come TrueIn recent years Potomac has added 3D Printing to our Digital Fabrication toolkit, integrating the additive manufacturing process with laser micromachining, micro CNC machining and other technologies to solve complex manufacturing problems. We’re pushing the envelope of 3D printing limitations…

-

Laser Marking an Historic H-3 Helicopter Rotor Blade

VIEW DETAILS: Laser Marking an Historic H-3 Helicopter Rotor BladeLaser marking Creates Remembrance for Marine Corp Veteran Potomac has had a long history working with U.S. government agencies over the years. Our first R&D funding came from the Small Business Innovation Research program that supported our UV laser and…

-

Potomac Collaboration with Fab Lab at the Community College of Baltimore County Proves to Be A Win-Win Public-Private Partnership

VIEW DETAILS: Potomac Collaboration with Fab Lab at the Community College of Baltimore County Proves to Be A Win-Win Public-Private PartnershipHow we helped Fab Lab Baltimore and in the process gained valuable workforce development. Potomac’s move to the UMBC campus has reaped a number of benefits for Potomac, one of which was most unexpected. The new facility is located about…

-

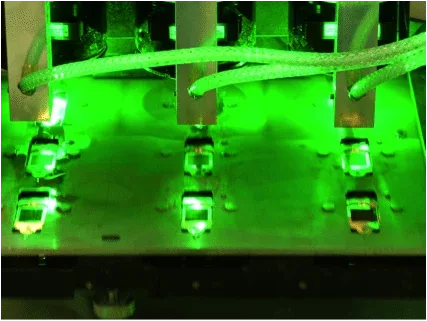

Potomac Photonics’ Economical Device Fabrication Expedites Stanford Microfluidics Research

VIEW DETAILS: Potomac Photonics’ Economical Device Fabrication Expedites Stanford Microfluidics ResearchStanford researchers find the flexibility and affordability of the Fast Track program the right fit for R&D in biotech microfluidics project. July 9, 2015; Baltimore, MD: Fast Track, recently introduced by Potomac Photonics specifically for affordable microfluidics device fabrication, has…