Another year has quickly passed and 2017 will soon be upon us bringing new opportunities and challenges in advanced manufacturing. It’s an exciting time to be working in a field where innovation is changing the factory floor.

At Potomac, we like to say, “This isn’t your father’s manufacturing”! From 3D Printing to artificial intelligence, the Internet of Things to robotics, and haptic software to big data, manufacturing is becoming “smarter”. Using these new tools, we are able to help our customers from the biotech, medical device, microfluidic, consumer products and microelectronics industries bring products with optimized designs to market faster.

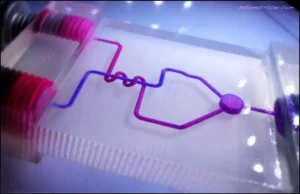

Static companies do not succeed; we must continually build upon a solid foundation of core competencies to expand capabilities. Potomac’s long history in laser micromachining is still a key process in our operation, but now we often combine this tried and true technology with other new tools and processes in order to meet our customers’ increasingly complex demands. Adding 3D Printing, micro-CNC, hot embossing and bonding to our toolkit has expanded our ability to give customers fast, economical turnaround in a one-stop shop.

Today’s products are pushing the limits of manufacturing processes. Applications that only a few years ago seemed like science fiction are now driving advanced manufacturing. Miniaturized microfluidic devices and targeted drug delivery systems require tiny feature sizes with higher accuracy placement; more complex geometries require sophisticated fixturing; and new materials are being employed, especially in 3D Printed parts. Products that are used from outer space to the inner body also give our work meaning, for we are helping improve lives in the 21st century.

In 2017 we will continue to provide job opportunities in the innovation economy to Baltimore-area talent. Today’s manufacturing worker must demonstrate a high level of problem-solving skills and knowledge of new technologies like digital fabrication and CAD software. Tapping into a generation that is exploring STEM topics in the hands-on maker movement, Potomac’s collaborations with UMBC, Fab Lab Baltimore, Open Works and the Community College of Baltimore County is leading manufacturing talent to new frontiers.

We expect yet more innovation in the year ahead, and look forward to playing a small part bringing advanced manufacturing solutions to life!