In the Pharmaceutical industry more and more drugs never make it out of the lab to reach the patients that need treatment. Costs are not only high to the companies that have placed big R&D bets to develop novel drugs, but also to the patients who cannot be helped and the insurance companies who must pay for the continued patient care these drugs could potentially eliminate. To stem this tide, researchers are now focusing on new techniques to improve drug discovery, disease modeling, and toxicity screening in order to speed time to market for new treatments.

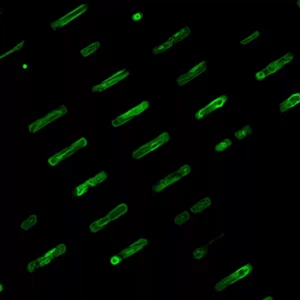

At the Cardiovascular Institute at Stanford’s School of Medicine, teams are exploring in vitro production of human cardiac progenitor cells and cardiomyocytes from human pluripotent stem cells in order to ensure a strong source of cardiovascular cells for research. Using stencils Dr. Joseph Wu, Principal Investigator as well as the Institute’s Director, has demonstrated the ability to pattern proteins to generate stem cell lines. The Cell attaches onto the stencil and grows into the prescribed shape required for research.

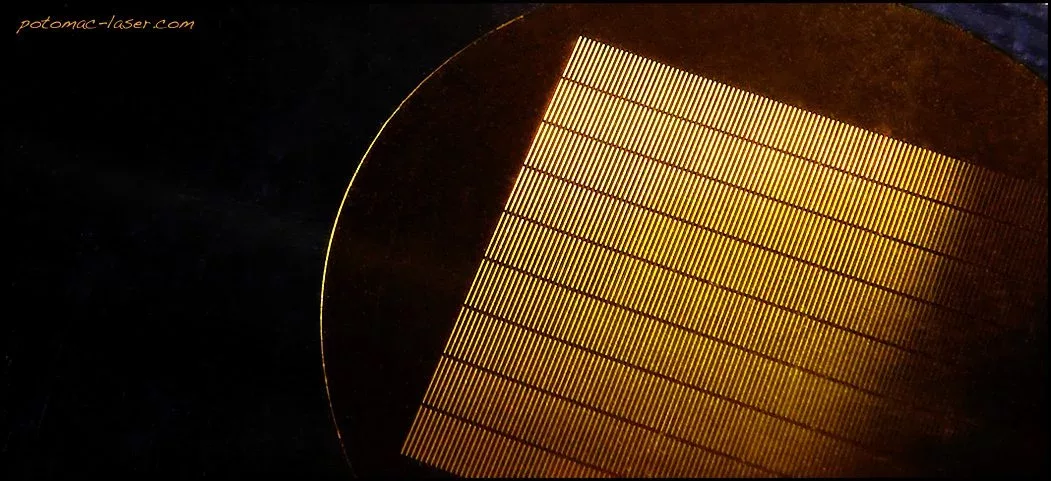

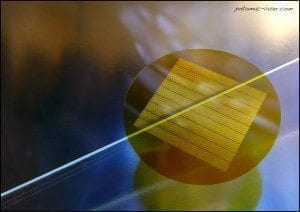

Huaxiao Yang, a post-doc on the team, was charged with creating stencils that are 20 mm in diameter with 6,500 holes. Having experience in stereolithography, Dr. Yang explained that he first tried to create the parts but quickly realized that laser micromachining polymer stencils may be a better solution, so he contacted us at Potomac. The holes were rectangles 16.7 microns by 110 microns in diameter and so Potomac’s laser processing made more sense. Dr. Yang, elaborates: “The size is ideal for laser processing plus digital fabrication does not require the generation of a mask. Going straight from a CAD file to the laser tool saved us both time and money, plus we can modify designs as needed, working iteratively with the Potomac team.”

In addition, the Stanford team needed repeatable results. The cells are evaluated using automated tools and so identical stencils were imperative to make a good comparison between the cells which were grown in each stencil. Potomac’s laser micromachining processing drills holes with high precision in both tolerance and accuracy, so that the entire 6,500 holes were very close to identical. Other materials are now being tested for manufacturing the stencils in order to optimize performance.

The Cardiovascular Institute’s work has another benefit to society. The Institute is compiling a bio-repository of patient specific, de-identified human induced pluripotent stem cell (iPSC) lines. Patients who are participating in the study, cover a broad spectrum of cardiac diseases, healthy controls, and non-cardiac disease controls in the hope of someday tailoring drugs to the particular characteristics of targeted patient populations. Improved methods of generating stem cell lines will advance precision medicine so that lives are saved and most importantly, treatment does not compromise the entire body.