We recently completed an exciting 3D printing project for Jhpiego and Johns Hopkins University. Jhpiego brings high-quality health care to women and families wherever they are… in the urban neighborhoods of Kenya, an isolated outpost in rural Haiti, the earthquake-affected areas of Pakistan.

We recently completed an exciting 3D printing project for Jhpiego and Johns Hopkins University. Jhpiego brings high-quality health care to women and families wherever they are… in the urban neighborhoods of Kenya, an isolated outpost in rural Haiti, the earthquake-affected areas of Pakistan.

Through the use of innovative approaches, Jhpiego puts research into practice, develops creative solutions to improve health care services, and strengthens the capacity of countries to save the lives of women and families today—while building sustainable health systems for the future.

Marton Varady, MSE is a Global Health Innovations Fellow at Jhpiego and describes the part that was 3D printed at Potomac Photonics:

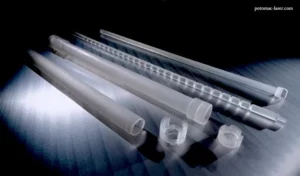

“These are prototype components of the SnowHorn and Applicator pieces of the CryoPop, a low cost, durable, and CO2 efficient cryotherapy device for treating pre-cancerous cervical lesions in the developing world. We needed these pieces to be made from a clear, non-porous material so that we could refine the SnowHorn design. The SnowHorn controls the formation of dry-ice within the Applicator chamber by appropriately expanding liquid CO2 until in precipitates as “snow”. The dry-ice within the applicator is then placed against the surface of the cervix to perform cryotherapy. Our development team is a partnership between the Center for Bioengineering Innovation & Design (CBID) at Johns Hopkins University and Jhpiego. Jhpiego is an international NGO present in over 50 countries where it is training the health care workers responsible for the care of women and their families.”

For more information on Jhpiego please check out www.jhpiego.org