Potomac Photonics now offers 24 hour turnaround on many polyimide (Kapton) cutting prototyping projects. All that is required to get started is a drawing.

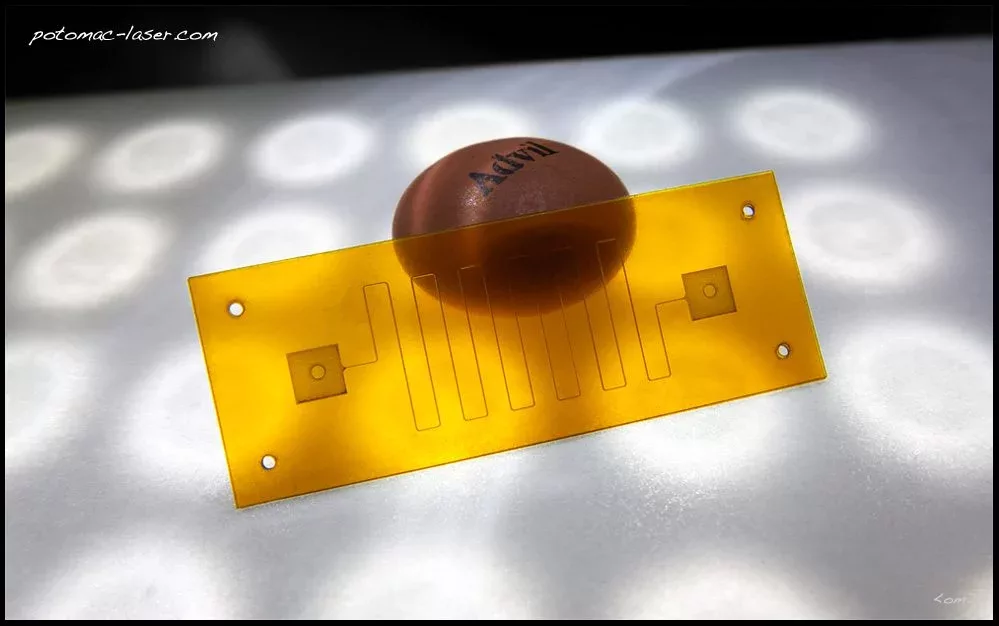

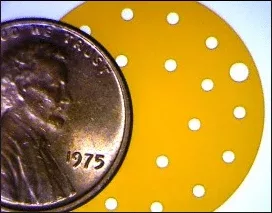

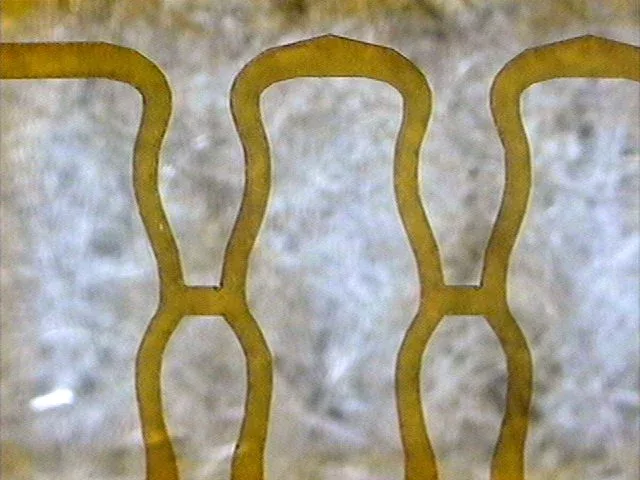

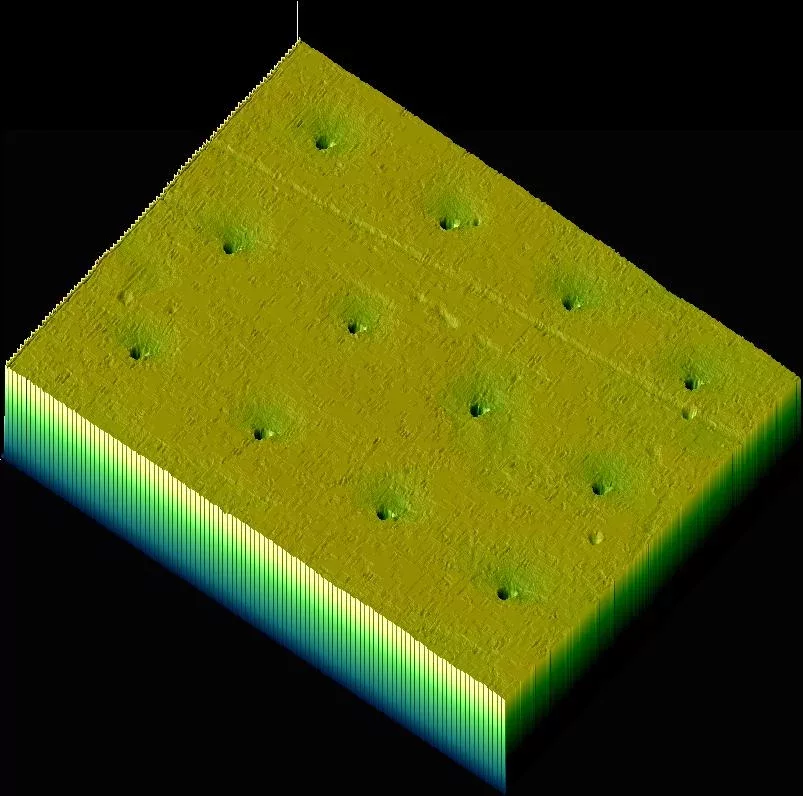

Laser cutting of polyimide is a popular method for precise cutting of thin sheets as the result is far more clean and accurate than alternative cutting methods. We can also do intricate shapes, high volume, various thicknesses and no tool wear

Potomac stocks Kapton material in 0.001, 0.002, 0.003 and 0.005 thicknesses. If we do not stock the material, we can typically have it in-house within a day through our partners at Goodfellow who carry a large range of Polyimide material.

Potomac has worked with several industries to develop and supply polyimide polymers including medical, biotech, electronics, aerospace and automotive with many of our products providing critical roles. Not only is our rapid turnaround highly desired but our accuracy with many items that play an important role of protection from heat, gaskets and seals, sensors and even body implants. Our committment to research, development and innovation ensures that we remain at the forefront of laser micromachining Kapton and other high performance materials.