2018 has proven to be yet another great year to be working in manufacturing, especially building micro devices for biotech, microfluidics, cancer research, medical diagnostics, microelectronics, consumer products and more.

Our customers continue to challenge us with problems that push the advanced manufacturing technical envelope. We especially appreciate these opportunities since we work with so many wonderful organizations that are innovating to improve human lives. Here are some highlights from 2018:

Laser Welding of Plastics

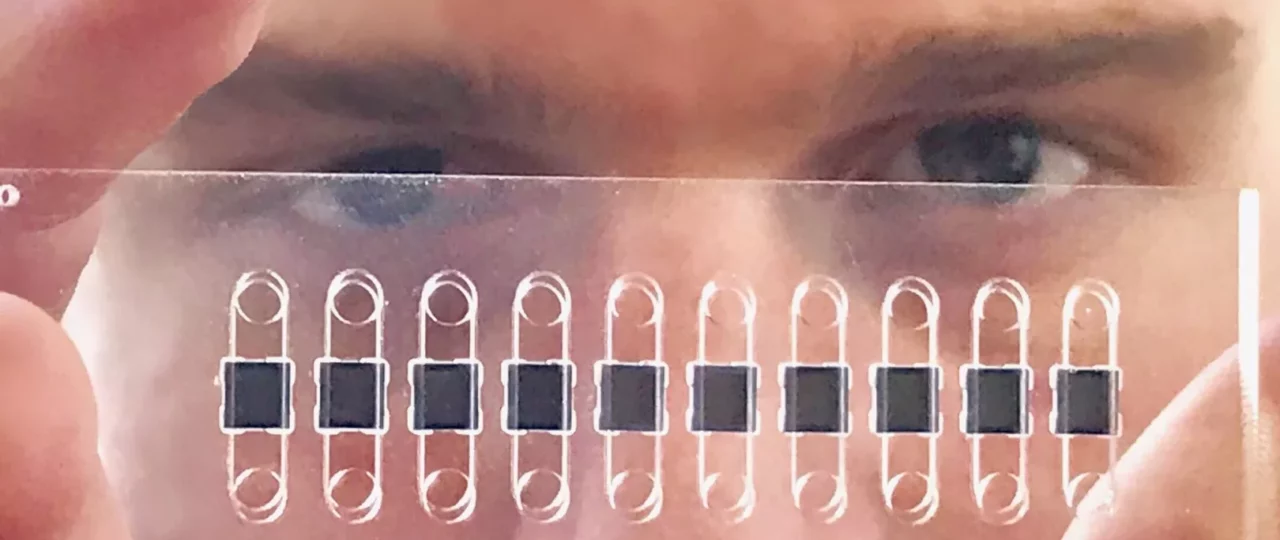

New work from our R&D team allows us to now laser weld plastics adding to our well-developed laser micromachining expertise. The Potomac laser welding process joins two plastic parts using a combination of heat produced by a laser and pressure provided by a clamping fixture. Laser welding is an excellent alternative to bonding in a variety of applications where adhesives are inconvenient or toxic including microfluidics.

3D Printing

Additive manufacturing technology holds the promise of totally new ways in which fabricate parts, and we continue to expand the possibilities of this new process. At the moment, 3D Printing is an addition to our toolbox on the factory floor, providing options when subtractive processes are not appropriate. This is especially true when we need to create complex geometries or rapidly prototype parts including tiny molds.

Collaborations with Local Institutions

Our location at BW Tech South gives Potomac access to top-rated education institutions that are producing world-class STEM [Science-Technology-Engineering-Math] talent. Internship programs with the University of Maryland Baltimore County and the Community College of Baltimore County have allowed us to develop our workforce. Interestingly, collaborations with the Maryland Institute College of Art have shown that good design skills are key to innovation in manufacturing and we have worked with excellent students who have chosen to come on board as full time employees.

The New Collar Workforce

This year Potomac was featured in a new book from Photonics Media Press on how digital fabrication is changing the nature of blue collar work with new technologies like 3D Printing, laser micromachining, microfluidics, robotics, and artificial intelligence. We are at the forefront of this change and look to a future where operators and technicians have engaging careers in advanced manufacturing.

Stay tuned for our predictions on what 2019 holds in store for new technologies and how we are continually expanding Potomac’s capabilities to help our customers solve challenging world problems. Happy New Year from everyone at Potomac!