2015 has yet again proven to be a great year at Potomac! We continually strive to be on the cutting edge [pun intended!] of digital fabrication by utilizing the latest tools for laser micromachining, 3D printing, CNC machining, laser marking and other manufacturing processes. But we go beyond just buying the best new machines.

Here’s how Potomac combines technology with innovation across departments to find the best solutions to our customer’s manufacturing problems:

Customizing tools and processes

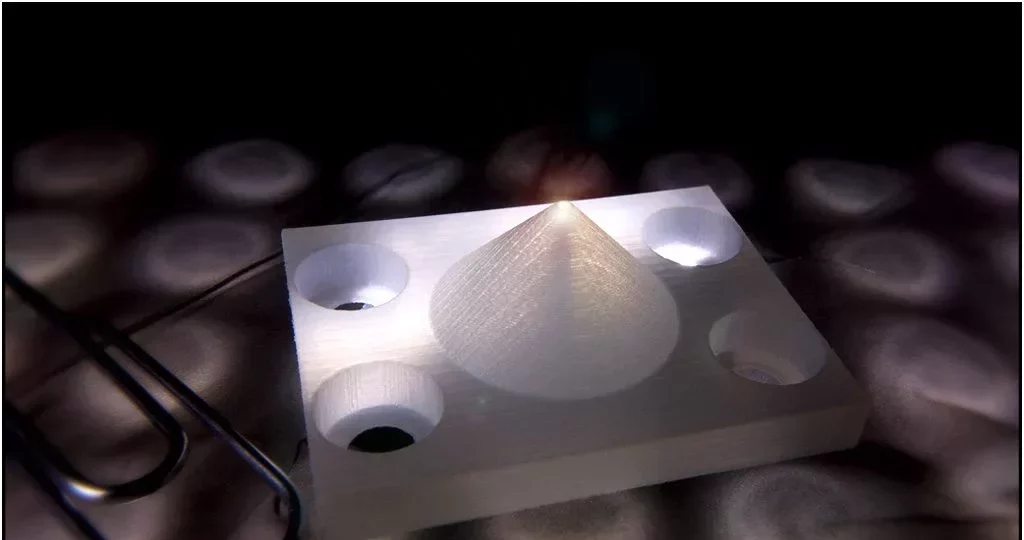

Potomac started as a laser equipment manufacturer so we are uniquely positioned to build upon the strengths of current technologies. In 2015 we brought in a number of new lasers and other technologies. With innovative engineering our team modified and customized these standard machines to fit next generation manufacturing processes. Only with technology and process innovation can we drive solutions to new customer product problems and help bring the products of the future to market quickly and economically. This is especially important for new devices in the fast paced biotech, microfluidics and healthcare industries.

Investing in employee training and empowerment

Every business is only as good as its people. Our staff, from the front office to engineering, production, QC and shipping are trained to understand that we are here to serve our customers. Whether helping get a delivery out the door on time or coming up with new ideas for manufacturing parts more efficiently, we value the innovations of our people and incorporate their passion into our work.

This year we forged a work-study relationship with Fab Lab Baltimore, located at the Community College of Baltimore County. By giving paid internships to students we are able to train the workforce of the future, and in the process, hire new employees who have the digital fabrication skill set needed for what President Obama called the Next Industrial Revolution.

R&D

We also continue to work closely with the University of Maryland, Baltimore County. Collaborations with engineering and science departments are expanding our R&D efforts to improve equipment and processes, as well as develop new technologies. Work continues on our advanced biotech program for fast turnaround, customized microfluidic devices, as well as for next generation embedded microelectronic devices.

Awards & Rewards

All of these efforts paid off in 2015. We were invited to present at NASA’s Capitol Hill Day in DC to demonstrate the kind of commercial products and services that have resulted from NASA R&D Funding. We were also proud to receive the New Directions Award from Baltimore County. The annual award is made to companies located in the county that are on the leading edge of engineering, manufacturing and/or technology that best represents the great potential of our business community, and the economic future of Baltimore County.

But the real reward comes in knowing that we advance the fields of biotech and healthcare, advanced manufacturing and product design. For it is with innovation that technology solves world challenges and improves life for all of us. So with the successes of 2015 behind us, we look forward to another great year. Happy New Year from all of us at Potomac!