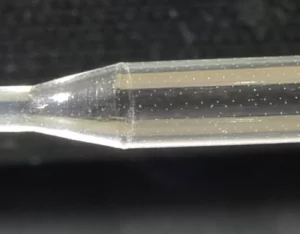

Precision drilling of micro holes in catheters including balloon and multi-lumen tubes with diameters as small as 2 microns.

Potomac Photonics has developed precision catheter hole drilling technology for several applications. With an emphasis on cleanliness and positional accuracy, our technology is suited for prototyping and production applications.

We have the capability to drill micro holes in almost any material, including:

- Polyimide

- Nylon

- Polystyrene

- Teflon

- Pebax

- Mylar

- LDPE

- Silicone

- and more…

Why Choose Laser Hole Drilling for Catheters?

- In the intricate world of medical device manufacturing, especially for catheter tubes, precision is non-negotiable. Traditional drilling methods often struggle to achieve the microscale accuracy and smoothness required. Our laser hole drilling technology provides a superior alternative by delivering:

- Exceptional Precision: Achieve exact hole dimensions with minimal deviation, ensuring consistent performance.

- Superior Surface Quality: Smooth edges minimize tissue irritation and enhance biocompatibility.

- Complex Geometries: Capable of producing intricate hole patterns and varying sizes to meet diverse design requirements.

- Efficiency: Accelerated processing times with reduced material waste, optimizing your production workflow.

- From Prototyping to Production

At Potomac Photonics, We Support Your Projects at Every Stage

Our Advanced Laser Drilling Technology

- Micro-Drilling Capabilities: Create holes as small as tens of micrometers, essential for intricate catheter designs and ensuring optimal fluid dynamics.

- High Repetition Rates: Maintain consistent and rapid production speeds without sacrificing quality, perfect for both prototyping and mass production.

- Non-Thermal Processing: Minimize heat-affected zones to preserve the integrity of sensitive materials, enhancing the longevity and performance of your catheters.

- Automated Precision Control: Utilize advanced automated systems for real-time adjustments and rigorous quality assurance, ensuring each hole meets exact specifications.

- Expertise in Premium Materials: Enhanced by the resources and support of our parent company, Goodfellow.

- The performance of catheter tubes is highly dependent on the materials used. Potomac Photonics excels in processing a wide range of biocompatible materials.

- Our specialized knowledge ensures that each material is meticulously processed to meet stringent medical standards and performance criteria.

Benefits of Partnering with Potomac Photonics

- Comprehensive Project Support: From initial prototyping to large-scale production, we handle every phase of your project with expertise and precision.

- Unmatched Quality Assurance: Our rigorous testing and quality control processes guarantee the highest standards in every catheter tube we produce.

- Customized Solutions: Tailored laser drilling services to meet the unique requirements of your catheter designs, ensuring optimal functionality and performance.

- Scalable Operations: Whether you’re developing a prototype or scaling up for mass production, our flexible capabilities adapt to your needs.

- Dedicated Support: Receive continuous technical support and consultation from our team of experts, guiding you from design to production.

Applications in Catheter Technology

Our laser hole drilling services are integral to the development and manufacturing of various catheter-based medical devices, including:

- Vascular Catheters: Ensure precise fluid flow and minimize blood damage for safer vascular interventions.

- Interventional Devices: Facilitate accurate drug delivery and enhanced device maneuverability for effective treatments.

- Diagnostic Tools: Enhance the functionality and reliability of imaging and sensing equipment with precise hole configurations.

- Therapeutic Catheters: Support effective treatment delivery with high precision, improving patient outcomes.

Partner with Potomac Photonics

- At Potomac Photonics, we are dedicated to advancing medical technology through innovative laser hole drilling solutions for catheter tubes. Whether you’re in the prototyping phase or ready for full-scale production, our expertise ensures your medical devices achieve the highest levels of precision, quality, and reliability.

- Contact us today to discuss how our specialized laser hole drilling services can elevate your catheter projects and drive your medical innovations forward.