There are many barriers to market entry for new biotech products, most of which start with demonstrating the feasibility of a new technology. However, once proof of concept is established in the prototyping stage, getting a product to market requires overcoming big hurdles in high volume manufacturing. Startups can only scale production with partners that provide the expertise to design for manufacturability and build a path to reduced costs and lead times from rollout throughout sales growth.

Potomac has the experience to help startups in this journey, having worked extensively with entrepreneurs in the microfluidics, medical device, biotech, consumer product, and microelectronics space. Dr. Philips, the co-founder of one of Potomac’s microfluidic customers, also points out that Potomac is willing to work with small companies that have promising technology like their novel particle characterization instrument. Not only was Potomac one of a tiny pool of contract manufacturers that could meet Dr. Philip’s company’s demanding technical specifications, we also saw the potential of the product to help the world and were the only vendor willing to make affordable parts for the startup.

Innovating Solutions

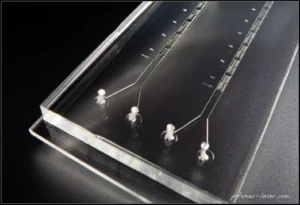

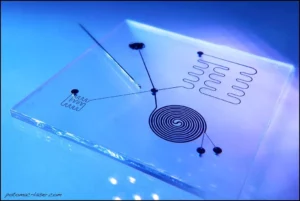

The microfluidic chip that delivers a sample to the customer’s instrument had challenging parameters for positioning accuracy, channel dimension accuracy and cut quality, as well as the need to scale economically in order for each test to be affordable for their customers. We are continually innovating solutions that build upon our knowledge base and created solutions specifically for our customers’ needs.

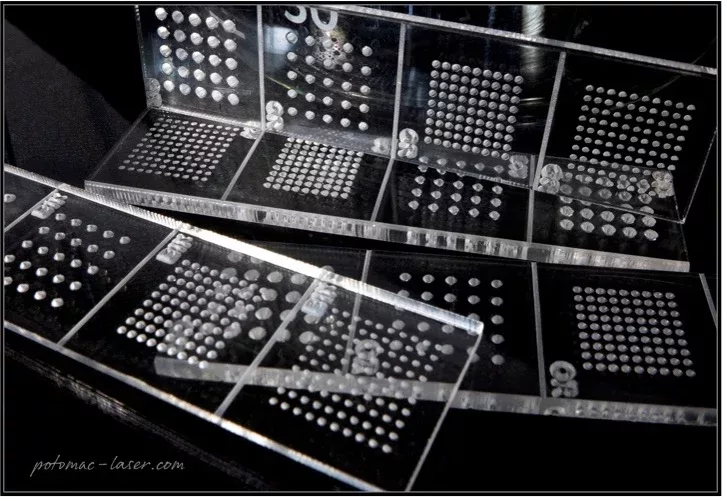

Key to our success is the depth of Potomac in-house equipment design, set up, calibration, and inspection/QC skills and the invention of unique processes using these tools. The customer’s microfluidic chip consists of 4 layers that must be accurately registered within 10’s of microns in order to allow the instrument to measure correctly. Potomac’s manufacturing equipment is highly accurate, but we also have developed methods to finely calibrate our machines in an entire factory system. As part of this coordinated platform, we are also able to build our own precision fixturing to perfectly align each part in the final assembly. Last but certainly not least, our automated inspection system ensures that each part meets customer requirements time and again.

Much of the cost of the microfluidic device was in the assembly step and we knew we had to invent new methodologies to bring down cost when manufacturing at high volume. To answer the challenge our Advanced R&D team developed a unique laser welding process that reduced bonding time, and also eliminated residues that could cross contaminate the microfluidic chip.

Prototype to Production

It is important to note that scaling from prototype to production relies heavily on a contract manufacturer with the understanding and competence in high volume production. Potomac’s prototyping team knows what to expect as a product makes its way to the factory floor from the R&D lab and can build a prototype that anticipates what lies ahead. The iterative design process allows customers to design, test, evaluate, then re-design to optimize all parameters. Breaking down the barriers of cost and speed translate to faster time to market with a product that has higher chance of sales success. And as sales climb, Potomac has the wherewithal to manufacture those products quickly and affordably to meet increasing demand.