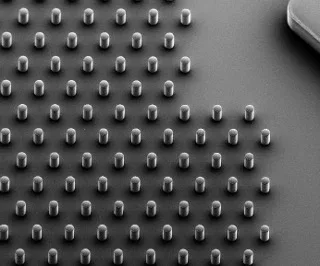

When it comes to microfluidics, packing purpose into every micron is a true design challenge. The design of individual features starts with defining their purpose in the overall function of the device. Today we are spotlighting one of these common features: micro pillars.

Micropillar arrays serve a multitude of purpose in the function of microfluidics. They are often used for concentratingbiomolecules such as DNA, RNA and Proteins and for mixing the reagents required to produce these biomolecules. Pillars can even be used as filters to separate and purify a biological solution by restricting the flow of the larger cellular components and debris. Micropillar arrays can also be functionalized (coated) with antibodies to detect the presence of viruses and circulating tumor cells (CTCs). Micropillars utilize large surface to liquid volume ratios to achieve all of these diverse tasks.

Fabricating micropillars is a core competency of the microfabrication team at Potomac Photonics. The biological applications that use micropillars typically require tight dimensional and surface roughness specifications that may only be achievable using specialized microfabrication technologies and tools. Photolithography is one method of producing high precision micropillars at the smallest micro and nano scales, while direct micro-CNC machining provides high quality results at greater dimensions. These technologies can be used directly to produce small quantity prototype devices, or in combination with a high-volume microfabrication technology (such as hot embossing) to deliver larger quantities for device proof of concept and testing.