Anna The Manufacturing Maven: Blog #1

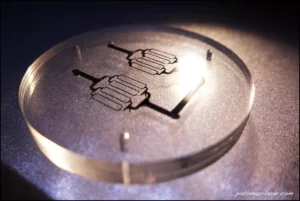

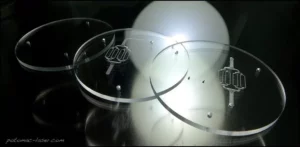

What are Microfluidic Devices?

If you know Potomac, you know that “Microfluidic” is a buzzword around here. But chances are, you don’t understand exactly what that means.

According to the National Cancer Institute, a microfluidic device is an “an instrument that uses very small amounts of fluid on a microchip to do certain laboratory tests. A microfluidic device may use body fluids or solutions containing cells or cell parts to diagnose diseases. [It may also be] called lab-on-a-chip.” Applications of microfluidics include medical research, efficient head trauma analysis, and various other uses (e.g. biotech, environmental, etc.).

One Size Does Not Fit All

Microfluidic devices come in many shapes and sizes, depending on performance requirements for the specific projects, as well as certain devices’ applications. Some microfluidic devices only require one or two channels and layers, while others are more intricate. Potomac engineers review each project and produce unique solutions for prototyping. Not only can microfluidics vary in look, but the means of manufacturing them may vary as well. Manufacturing processes involving microfluidics include laser machining, micro-CNC, hot embossing, precision alignment and alternating bonding technologies. Stay tuned for future blogs that will examine these areas more closely.

What Makes Potomac Special When it Comes to Microfluidics?

Potomac Photonics has revolutionized the manufacturing process for microfluidic devices. The demand for these devices is strong and the previous ability to acquire them were scarce. However, with our brightest minds working together, we have created standard methods that we can easily customize to cater to our customers’ needs.

President and CEO Mike Adelstein likes to think of us as a “one-stop shop.” While customers previously had to consult multiple companies to make a microfluidic device, our innovative labs allow them to complete the entire process, start to finish, with Potomac. Adelstein stresses the importance of a “manufacturing toolbox,” which we build so that customers can give us a quote and we can select a “tool” that will be useful towards producing their parts.

This new standardized method allows efficiency and consistency throughout all our work.

Potomac strives to develop innovative processes that enable our customers to have access to the best fabrication technologies. Our passion for advanced manufacturing only grows with these new methods. Anna is excited to explore this exciting field, and share her findings with her new blog, “Manufacturing Maven.” If you have any comments or ideas for future blog posts, don’t hesitate to contact Anna, at: [email protected]