As a leader in Advanced Manufacturing Technologies, Potomac Photonics is pleased to introduce its new series recapping the latest news and stories from our exciting industry.

In 1983, Charles Hull thought of shining a controlled beam of ultraviolet light on chemical polymers to create new objects, 3D printing is all around us and here to stay.

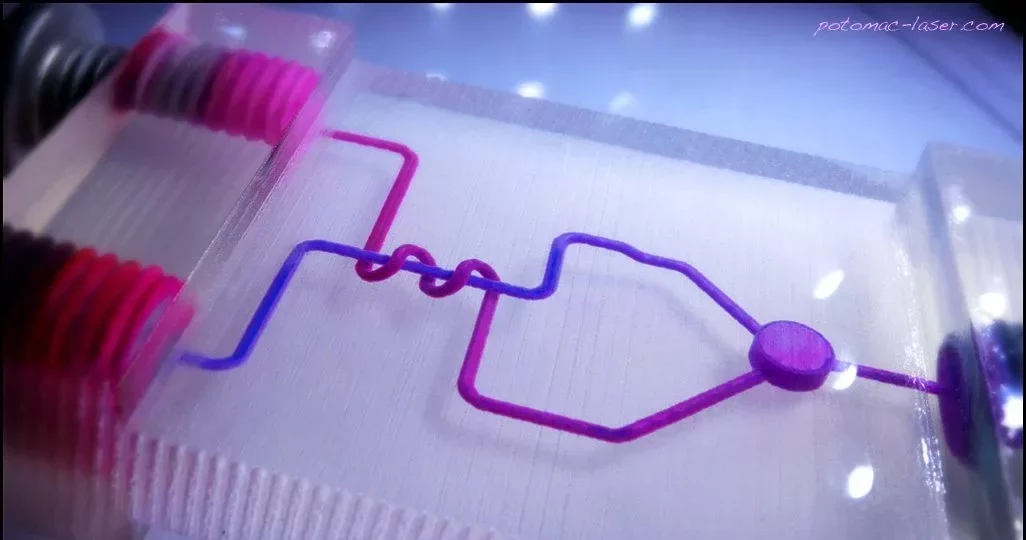

According to Shane Fox (Link3D), in his article in Industry Week magazine “The Future of Advanced Manufacturing : Design for 3D Printing and Implementation of Digital Factories,” cooperation between engineers and manufacturers will bring 3D printing over the threshold and into the future. 3D printing is implemented on a global scale by aerospace and medical industries to create light weight parts with new materials. Currently, we encounter 3D printing every day in places we might not even expect : in the engine of a taxi cab , an artificial knee, or the nozzle of an airplane (Potomac Photonics utilizes 3D printing to enable our customers to fabricate complex micro parts such as a middle ear prosthesis for the University of Warsaw). The versatility of 3D printing – additive manufacturing –implementing laser light, affords the ability, for example, in metal manufacturing to create parts with unique materials, and unique shapes. Amazing strides have been made in the speed of design to post-production: This is called Rapid Prototyping. The technology industry is looking to deepen the understanding of advanced 3D processes to better enable its potential. The “promise of complexity” will be kept in the creation of diverse products, using new materials, and accessible 3D designs. How can we achieve this? With the creation and integration of new software that will interface with 3D printers, and make 3D design more accessible, streamlined and mainstreamed. Doing this requires cooperative synergy between industrial designers, mechanical engineers, and material scientists. Things that we once thought were just dreams will become reality. Someday soon, for example, we may be able to manufacture a robot that can help people with limited mobility lead more independent lives.

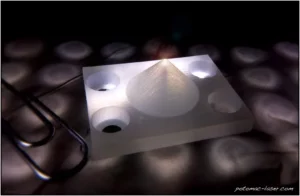

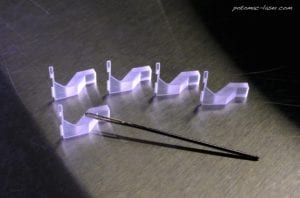

Potomac Photonics continues to build and optimize our Digital Factory that enables our customers to have their parts 3D Printed, Laser Machined, Joined and Assembled quickly, and cost effectively. Recenly, we introduced the Potomac Proving Ground which allows customers to have certain prototypes fabricated as quickly as 24 hours. We look forward to partnering with companies such as Shane Fox’s company Link3D to further our development in this area.