2016 promises to be another year of explosive innovation in advanced manufacturing. Several emerging applications, especially in the biotech and medical device industries, are driving Potomac Photonics to deliver ever more complex and sophisticated solutions to these new challenges. Here are some highlights of what we see ahead for the coming year:

Miniaturization for Targeted Drug Therapy

Several new biotech areas are bringing product miniaturization to smaller and smaller spatial scales. Targeted drug therapy is one field that we find especially exciting since the new methods deliver drugs directly to the affected area. In the case of chemotherapy, not only does a malignant area get a higher dose of the pharmaceutical, the side effects of systemic dosing are eliminated. No longer do patients with a specific cancer, have to worry about their immune system being compromised or another cancer forming due to total body exposure. So we are not only saving a life, we are also improving quality of life for the patient.

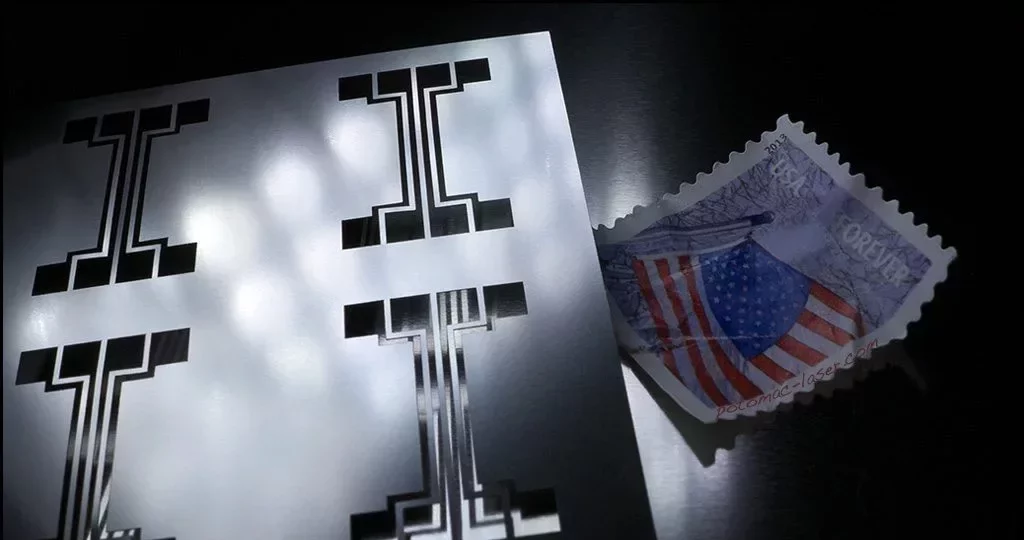

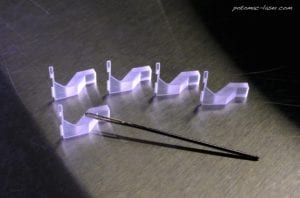

As you would imagine, targeted drug therapy requires totally new and much smaller delivery systems. Potomac’s micro-fabrication expertise is a solid foundation from which we are pushing the limits of small. Our ability to repeatably laser drill holes as small as 1 micron with tight tolerances is key to manufacturing these new medical devices. We also have extensive background in parts-handling systems for these tiny biotech products that are often made of thin, fragile materials such as glass or silicon. In many cases we have had to also create fixtures in-house in order to drill holes in a part or otherwise fabricate new medical devices that were too small to be held in a traditional method.

Customized Bio Tech Rapid Prototyping to Speed Time to Market

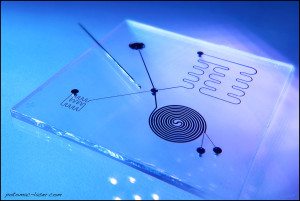

With today’s 24/7 connectivity, faster time to market is increasingly important for new products. When working on very small devices, the time constraints inherent in photolithographic processes often slow down getting a new device on the market and are also quite expensive. Digital Fabrication that is based on Potomac’s CAD-driven machines solves this problem. For applications such as manufacturing custom microfluidic devices, we have a streamlined process called Fast Track.

Potomac’s FAST TRACK program generates and precisely replicates channel designs in your substrate. In addition, we laser micromachine vias and holes, then bond cover slips. To keep prices low, we have specific design parameters listed on the FAST TRACK website page. For any microfluidic designs that don’t fit into the FAST TRACK low cost design parameters, we are happy to work closely with you to develop a manufacturing process suited to your specific application.

New Advanced Manufacturing Technologies With the advent of 3D Printing, entirely new technologies are emerging on the 2016 factory floor. New 3D Printers are combining additive and subtractive manufacturing processes in one machine and new materials are added every day to the 3D Printing repertoire. Laser technology, from fiber lasers to ultra short pulse sources, is moving quickly to increase performance and reliability. At Potomac, we continually test and source new tools in order to best meet the demands of our customers’ next generation products.

At Potomac, we look forward to meeting these and other new challenges with the innovation for advanced manufacturing that is our hallmark!