Engineering is a process, a continual development of new techniques to improve products so that we can expand their usefulness via better performance, longer lifetime and reduced cost. And it’s even more gratifying when the engineering process improvement saves more lives. Recently, Potomac had the opportunity to do just that in work for the Department of Neurosurgery at the University of Florida [UFL].

Hydrocephalus and Brain Drains

Ventricular drain catheters, fondly known as Brain Drains, remove cerebrospinal fluid from the ventricles in patients with hydrocephalus, an illness where excess fluid in the brain increases intracranial pressure leading to coma or death if not treated quickly.

According to the Hydrocephalus Association over 1 million people in the United States currently live with hydrocephalus and it is estimated that more than 700,000 Americans have a version called Normal Pressure Hydrocephalus, but less than 20% receive an appropriate diagnosis. For every 1,000 babies born in this country, one to two will have hydrocephalus and the disease is the most common reason for brain surgery in children.

For many patients shunt systems to drain brain fluid are a lifesaver. However, these catheters are not perfect and 25% of them fail either due to clotting issues or tissue growing into the catheter holes needed for draining fluid. Led by Project Coaches Dr. Frank Bova, Professor of Neurosurgery, and Dr. Christopher Batich, Professor of Materials Science and Engineering, the Brain Drain Team at UFL is exploring and developing novel methods to prevent and clear catheter occlusion using novel coatings, tip shapes, and hole geometry. Eliminating device replacement in patients could provide significant cost savings, plus improve comfort for anyone with the disease.

Re-engineering the Current Design

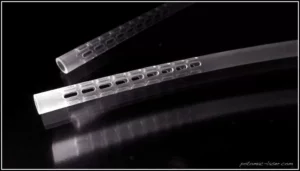

Samantha Solaski, Brain Drain Team Member, explains that the project’s goal is to demonstrate an operational prototype catheter that limits occlusion formation and can be cleared with an assistive device if necessary. The current silicone catheter has a series of punched circular holes to drain the brain fluid. The group wanted to test smaller holes and try different shaped holes, and also a novel network of interconnected holes.

Being cranial catheters, the size of the overall catheter is already quite small. The outer diameter measures just 3.4 mm. To reduce the size of the holes, Samantha realized they had to go from punching holes to laser micromachining. However, none of the local vendors in Gainesville could achieve the small hole size needed. Through an Internet search the researcher found Potomac who had no problems with the spatial scale.

Notes Potomac President and CEO Mike Adelstein, “We routinely drill holes that are between 1 and 200 microns. Also, for us, medical grade silicone is a familiar material. Unlike other organic polymers like Kapton, silicone exhibits unique properties that make it especially hard to process either mechanically or with lasers. Over the years we’ve developed laser hole drilling techniques for these medical grade materials that give outstanding results.”

Being as the Brain Drain Team was testing various prototype designs, hole size and accuracy were also important. Repeatability of hole dimensions ensured they could accurately compare designs.

With the help of Potomac’s laser micromachining expertise, the Brain Drain Team is improving medical devices to improve the quality of life for Hydrocephalus patients and who knows where else these engineering process improvements may lead!