We are asked often what exactly is Digital Fabrication?

Digital Fabrication, also known as direct manufacturing or on-demand manufacturing, has been around since 1952 when engineering researchers at MIT wired a computer to a milling machine to create the first Computer Numerical Control or CNC machine. The computer essentially became the “brains” of the machining process.

Whether used for 3D Printing, laser cutting, CNC machining, milling or welding, the process is the same. A digital version of a mechanical drawing called a Computer-Aided Design [CAD] file instructs the machine as to where to cut, drill, weld or in the case of 3D Printers, lay down material.

Digital Fabrication brought about radical changes on the factory floor. The accuracy of a computer is repeatable and consistent, increasing the quality of goods created on a CNC machine. CNC machines are also often faster and can work with minimal supervision, reducing labor costs.

However, one of the most powerful aspects of Digital Fabrication is the ability to quickly and easily make design changes since all that is required is modifying the CAD file.

Digital Microfabrication

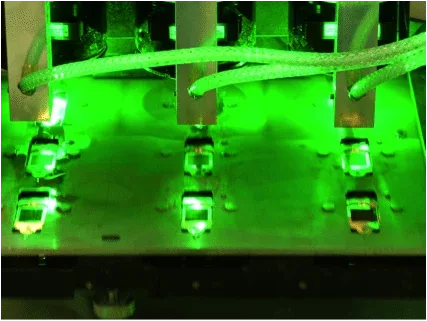

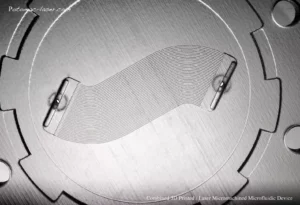

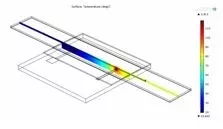

Potomac Photonics has expanded Digital Fabrication to the micro world with specialized tools such as laser micromachining, micro CNC machining, hot embossing, micro hole drilling, and high resolution 3D Printing. CAD drawings still drive the manufacturing process but on spatial scales as small as 1 micron. This unique expertise has optimized processes so that we can choose the right tool for the Digital Microfabrication job.

At Potomac, we start with advanced Modeling and Simulation (M&S) and take the process through to completion with high performance Quality systems to accurately measure results. Every step along the path in Potomac’s “Factory of the Future” is designed to expedite taking new products from prototype to production with reduced costs, faster turnaround times, and improved part performance. Contact us about your digital microfabrication project today.