Potomac is a leader in laser drilling of calibrated holes for leak testing applications.

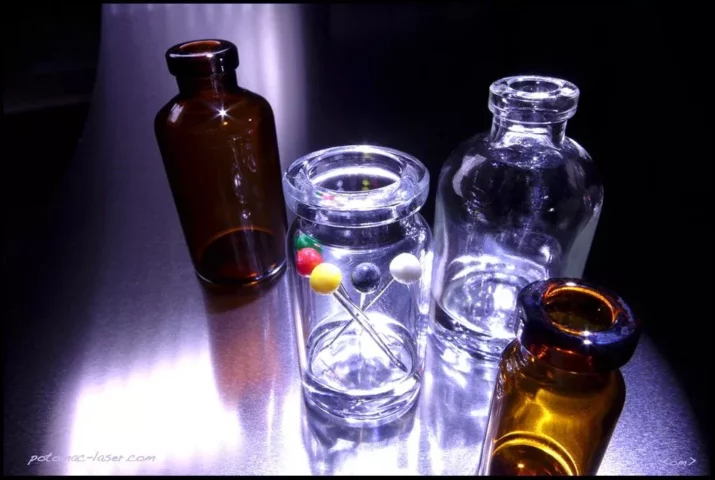

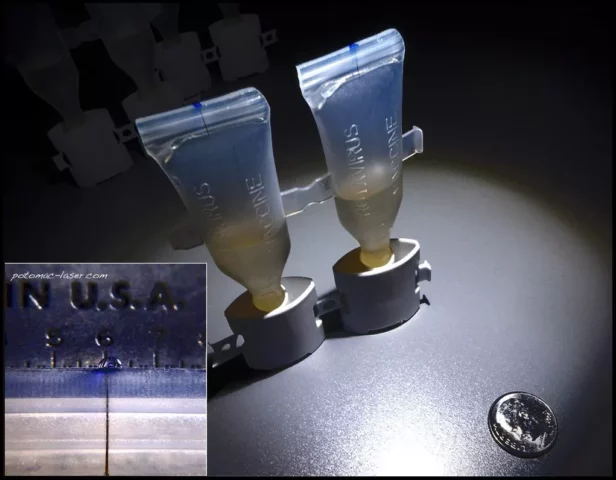

Potomac is able to laser drill micro-holes into glass and polymer vials/ampules for the purpose of leak test hole system validation. A range of hole sizes can be created in order to replicate defects in vials for use when calibrating leak detection devices. Depending upon the wall thickness of the vial/ampule, hole sizes can be as small as 1µm. In addition to vials, foil and blister packs can also be laser drilled. Potomac Photonics is ISO 13485 certified, and we have drilled hundreds of thousands of packages for the pharmaceutical, food and medical industries.

Leak testing or Container Closure Integrity Testing (CCIT) is an assay that evaluates the adequacy of container closure systems to maintain a sterile barrier against potential contaminants. Contaminants that could potentially cross a container closure barrier include microorganisms, reactive gases, and other substances (USP <1207>). Container closure systems should maintain the sterility and product quality of sterile final pharmaceutical, biological, and vaccine products throughout their shelf-life (Ewan, S. et al., 2015).

Container closure systems are composed of primary and secondary packaging components (USP <1207>). Primary packaging components are those that come into direct contact with the product, such as glass vials or syringes. Secondary packaging components play a critical role in ensuring proper package assembly, such as aluminum caps placed over stoppers (USP <1207>). (Source: American Pharmaceutical Review)

The advantages of laser-drilled leak test holes include:

- Realistic Defects: They closely resemble natural defects in glass (e.g., cracks) and polymers (e.g., pinholes).

- Precision: Tight tolerances can be achieved across various materials and thicknesses.

- Customization: Hole diameters and calibration packages can be tailored to meet specific customer requirements.

A Certificate of Conformance and Quality Data Sheet is included with each Leak Test Hole Drilling Order.

- Leak test holes as small as 1 micron.

- Accurate leak hole placement.

- Expedited delivery if required.

- Our measurement equipment is calibrated utilizing a NIST traceable standard.

- We have partnered with industry leaders to provide them with leak test holes that are compatible with all detection technologies.

Our customers partner with us to drill leak test holes for testing methods such as:

- Electrical Conductivity and Capacitance Test (HVLD)

- Laser-based Gas Headspace Analysis

- Mass Extraction

- Pressure Decay

- Tracer Gas (vacuum mode)

- Vacuum Decay

Industries / Application include:

- Pharmaceutical

- Medical devices

- Biotechnology

- Food / Packaging

Packaging:

- Vials

- Ampoules

- Pouches (filled or unfilled)

- Bags

- Filled and sealed bottles

- Metal containers

- Foil and blister packs