Potomac Photonics has a broad range of technologies and processes to micromachine almost any type of polymer material on the market, with features both small (down to a micron) and large. With the added benefit of being able to handle projects ranging from single prototypes up to full production runs of millions of parts, Potomac is truly your one-stop manufacturing solution. Examples of projects or applications that we have helped our customers develop and bring to market include:

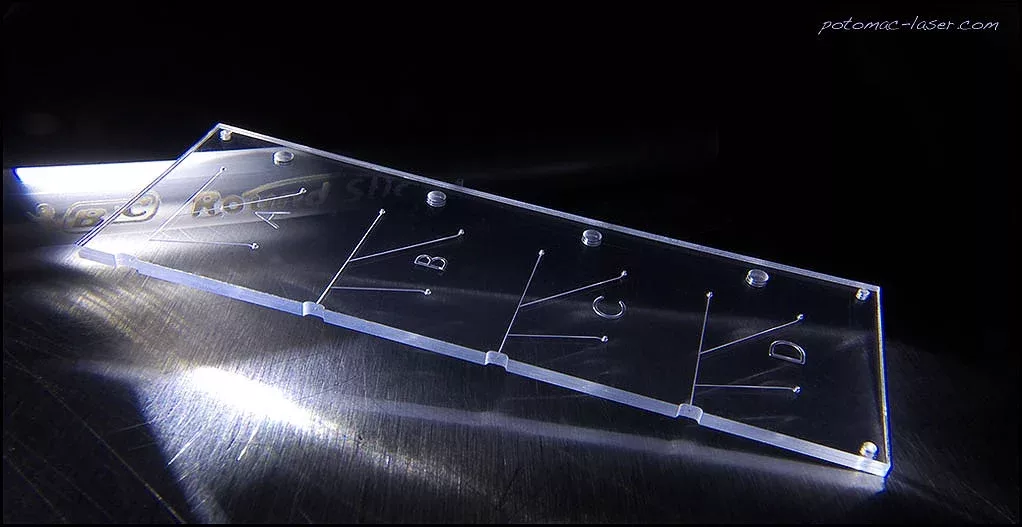

- Fabricating custom plastic parts

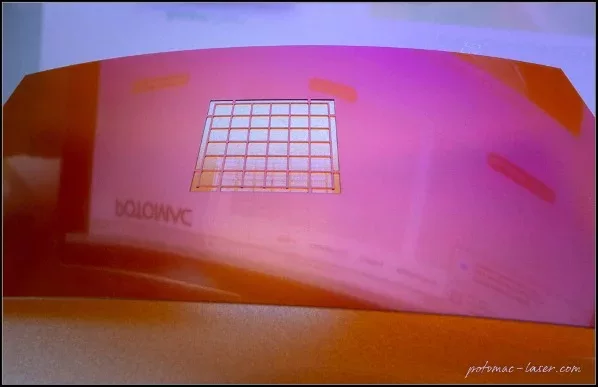

- Patterning of metalized plastics

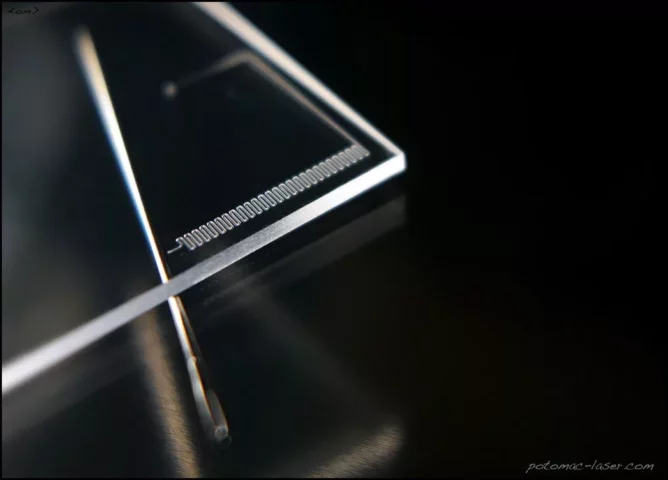

- Precision cutting of polymer and plastic sheets

- Part singulation

- Polymer circuit excision

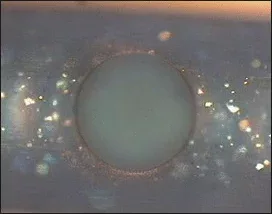

- Small hole drilling in almost any type of polymer material

- Blind channels and holes

type of plastic material

Types

We can machine almost every type of plastic material, including:

A polyimide film developed by DuPont is used across a wide range of industries and applications, including consumer electronics, solar photovoltaic and wind energy, aerospace, automotive, medical devices, and biotechnology products. It has good insulation and temperature characteristics and is available in many types, sizes and thicknesses. Potomac carries Kapton HN and VN material on the shelf and can turnaround custom parts in as quickly as 24 hours in some cases.

Polyether ether ketone (PEEK) is a colorless thermoplastic polymer typically used in medical, biotech, aerospace and automotive applications. It has a high tensile strength, has a wide temperature range and is very resistant to wear. Potomac has extensive experience fabricating precision PEEK parts such as microfluidic devices and complex automotive parts.

Polycarbonate is one of the most widely used thermoplastics because it is highly durable, extremely scratch resistant and very inexpensive. Also known as Lexan, Makroclear and Makrolon, it has been used by almost every industry including automotive, defense, medical device, biotech, electronics, alternative energy, etc.

Biaxially-oriented polyethylene terephthalate (BoPET) is a polyester film used by many types of biotech, electrical and packaging applications. Also known as Hostaphan/Melinex and Mylaru, BoPET is one of the many materials that can be metalized with conductive coatings such as ITO and patterned by Potomac Photonics.

Nylon, also known as polyamide, is a highly durable synthetic polymer. It is available in many different types of configurations. Potomac has machined precision features in nylon, including blind channels in nylon rods, for a medical device application.

Acrylonitrile butadiene styrene (ABS) is a thermoplastic widely used for manufacturing mechanical parts and components. It is an extremely tough material with good heat resistance and is available in many different types and colors. In addition to machining complex ABS parts, Potomac has the capability to laser mark ABS quickly and cost effectively.

Potomac Photonics stocks a wide range of these polymer materials. If we do not have a specific material in stock, we can quickly source it from our network of qualified suppliers. Our goal is to be your one-stop shop for custom plastic parts and materials. In addition, we do not have any minimum quantity policy, so you do not have to purchase more parts or materials than you require.