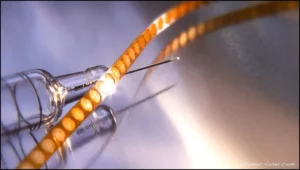

Laser Micromachining Polymer Machining (Polyimide (Kapton), PEEK, PET (Mylar), polycarbonate and others) Changing a work surface with light

- Type of polymer being micromachined and its absorption spectrum are critical in determining the optimal laser source to use.

- Typically, matching the low transmission point of a given material to the corresponding laser wavelength yields the most favorable results.

- UV Lasers produce “cooler” excitation in polymers, which results in an extremely clean cut quality with a minimal heat-affected zone (HAZ).

- Key considerations when choosing the appropriate laser source include desired cut quality, feature size and throughput.

- There is a wide spectrum of process parameters that can be optimized in order to meet quality and cost targets. For example, shorter laser pulses can improve cut quality and reduce the heat-affected zone.

- The smallest feature size achievable with a UV laser source is about 1 micron.

- Potomac stocks many types of polymers including Dupont Kapton (polyimide), Mylar (PET), PEEK, Polycarbonate and others.

- Potomac has almost every laser wavelength in-house, including UV systems at 193nm, 248nm and 355nm.

- Potomac can offer expedited Polymer Machining services with turnaround times as quick as 24–48 hours.