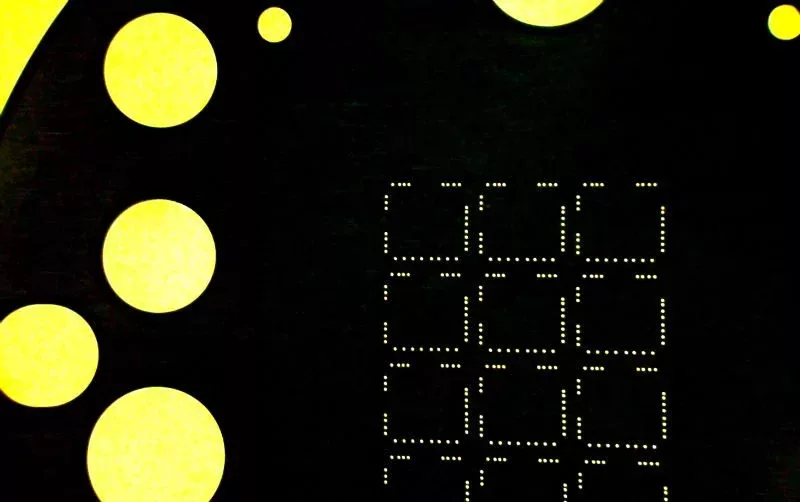

Micro-hole drilling for probe card applications can be effectively performed in a wide range of materials, including silicon nitride, polyimide, Ultem, and more.

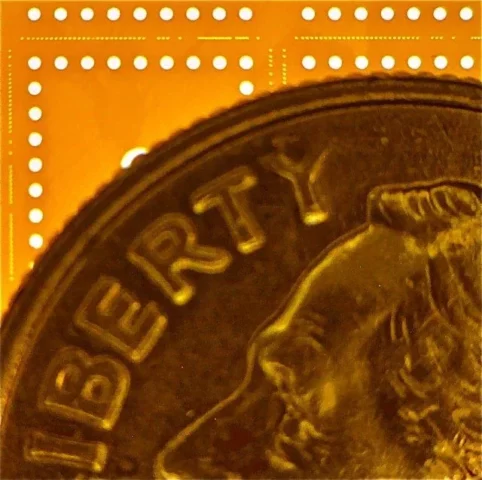

Micro holes as small as 2 microns can be laser drilled with very tight positional tolerances over large areas. Depending on the desired thickness of the material, controlled tapered micro holes can be drilled to exact specification. Larger holes for assembly and orientation can also be drilled utilizing the same technology used for the micro holes.

Micro laser drilling is the preferred method for probe card drilling due to its numerous advantages:

Versatility: Lasers can create a wide range of hole shapes, including circular, square, conical, and rectangular.

Precision: Lasers offer unparalleled control, ensuring accuracy and detail.

Consistency: Programmable and non-wearing, lasers deliver reliable results over extended production runs.

Speed: Lasers meet the high demands of swift manufacturing cycles with remarkable efficiency.

Quality: Ultrashort pulsed lasers minimize thermal impact, enhancing material quality and ensuring superior results.