Since 1982, Potomac Photonics has been setting the standard for laser micromachining services.

Rapid Turnaround Laser Micromachining Services for Prototyping and Production Projects

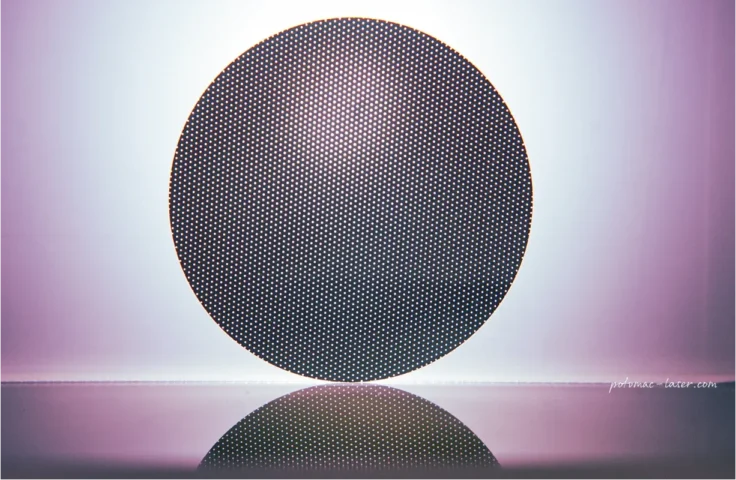

Potomac Photonics offers a broad range of cost-effective and highly repeatable laser micromachining capabilities that are available for applications ranging from prototyping through production manufacturing. With a variety of laser sources from deep UV excimer to Nd:YAG lasers, we can micromachine most materials (e.g. polymers, metals, ceramic, glass). Our engineers will choose the most appropriate laser system to micromachine your parts, based on feature sizes, tolerances, volume, and material.

- 193nm

- 248nm

- 266nm

- 355nm

- 532nm

- 1064nm

- 10600nm

Visit our Gallery to see examples of:

We are continually developing new laser micromachining capabilities and have been recognized by many of our customers for developing processes to manufacture their parts where others have fallen short. Our laser micromachining systems are equipped with some of the most cutting edge optics configurations, motion systems and parts handling fixtures in the world. We take pride in pushing the limits of laser micromachining technology from a process, quality and cost perspective.

In addition to laser micromachining parts, we have successfully developed applications for the fabrication of molds and fixtures that require small features and tight tolerances. For example, we can laser micromachine a mold for hot embossing applications, typically in less than a day.

For more information about micromachining please see:

Potomac specializes in laser micromachining services tailored to your polymer needs, leveraging extensive experience with a diverse array of materials. From microhole drilling in balloon catheters to precision applications, we’ve worked with materials like Kapton, Cirlex, PEEK, polystyrene, PMMA, polycarbonate, PTFE, Mylar, and more. Our meticulous selection of laser wavelengths aligns with your polymer’s absorption spectrum, ensuring optimal results with minimal heat affected zones. We prioritize delivering cost-effective solutions, balancing factors like cut quality, feature size, and throughput through precise process optimization. Trust in our expertise and advanced laser capabilities, including UV systems at 193nm, 248nm, and 355nm, for precise and efficient polymer micromachining solutions tailored to your industry needs.

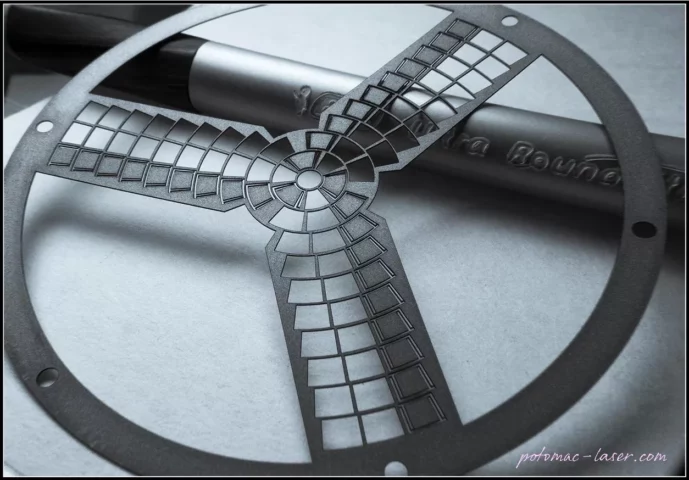

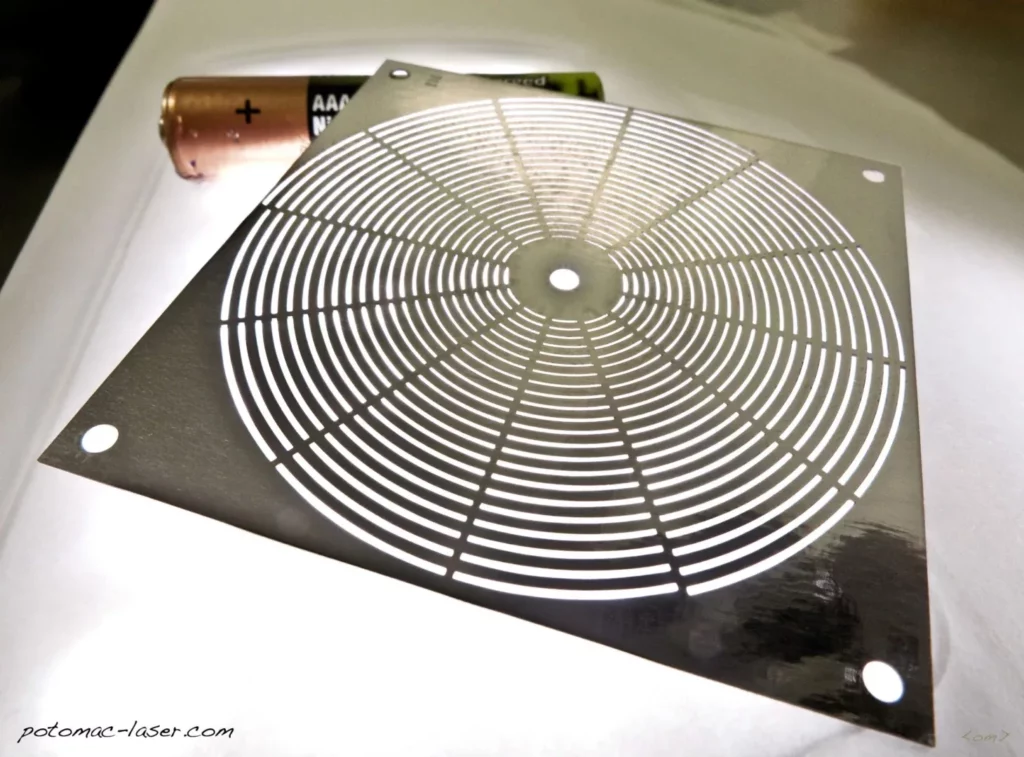

We excel in laser micromachining services for metals, offering precision solutions tailored to your needs. From stainless steel and copper to nitinol, tantalum, gold, aluminum, and more, we have extensive experience with a wide range of materials. Our process is driven by critical factors like metal type, reflectivity, and desired feature size, ensuring optimal results with minimal heat affected zones. We utilize advanced IR lasers for quality and cost effectiveness, though UV lasers are suitable for finer features and thin metal thicknesses. With our CAD to FAB driven technology, we eliminate the need for costly masks or tooling options, making custom part manufacturing efficient and cost-effective. Whether you need prototypes or production parts, our laser micromachining delivers fast turnaround times.