Potomac is more than just a contract manufacturing company. We strive to solve the difficult problems that impact humanity.

Much of our work has been focused on advancing healthcare. Our manufacturing innovations have helped nearly blind people see, allowed point of care diagnostics to ensure best treatment options for patients, and enabled precision medicine to deliver life-saving therapies.

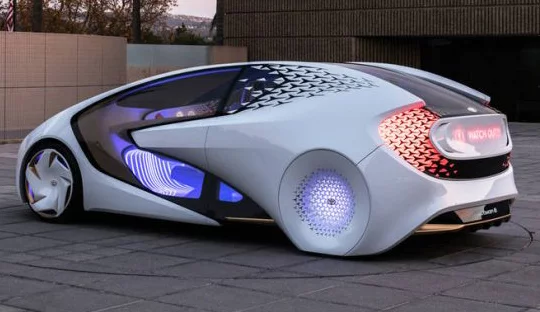

Electric Vehicles

The US Environmental Protection Agency {EPA} reports that the largest contributor to greenhouse gas emissions at 27% come from transportation by burning fossil fuel for our cars, trucks, ships, trains, and planes. Over 90% of the fuel used for transportation is petroleum based, which includes primarily gasoline and diesel.

Today, innovations from companies like Tesla, Volkswagen, and Volvo, the alarming rate of climate change impact, and the increase in fuel costs due to the war in the Ukraine, are driving consumer demand for EV’s that can lower mankind’s impact on climate. We see more EV’s on the road and with that comes need for more sophisticated battery technology.

EV Batteries

The heart of any electric vehicle is the battery that stores energy to power a car, truck or other mode of transportation. Manufacturing an EV battery involves a number of complex steps, many of which borrow from other advanced manufacturing technologies.

For example, the same laser micro-machining that can manufacture microfluidic devices can also quickly and economically cut and pattern the thin foils in EV batteries. Metal fabrication using lasers has been a staple on automotive factory floors for decades because most metals absorb laser light easily.

EV Batteries vary but in general metals like copper, aluminum, lead, tin, and nickel are common, while rare earth metals like lithium and cobalt also make up the EV Battery cell. Laser materials processing of these metals, along with the plastics like PVC, PET, and polystyrene used in the battery housing results in a smaller Heat Affected Zone [HAZ] when the laser wavelength is optimally matched to the specific material.

Manufacturing at the Speed of Light

Potomac’s manufacturing expertise extends beyond the technical parameters of fabricating parts. Starting with truly high-speed rapid prototyping, we are able to optimize functional prototypes through an iterative process with product designers. Focus on Design for Manufacturability ensures a smooth transition then to high volume production.

Our rapid turnaround is, in part, due to this attention to the final manufacturing process at the earliest stages of a project. Depending upon the size of the individual part, we can produce thousands of parts per week.

Potomac’s highly automated quality control processes also ensure that parts meet spec. Speed without quality is not acceptable in this consumer-driven EV battery market.

Saving the Planet

We believe that innovation is how mankind’s big problems can be solved. Potomac’s innovation in all areas of manufacturing – from laser technology and tools on our factory floor to automated QC and Design for Manufacturing – is exactly how we are battling problems like climate change through EV Battery production.