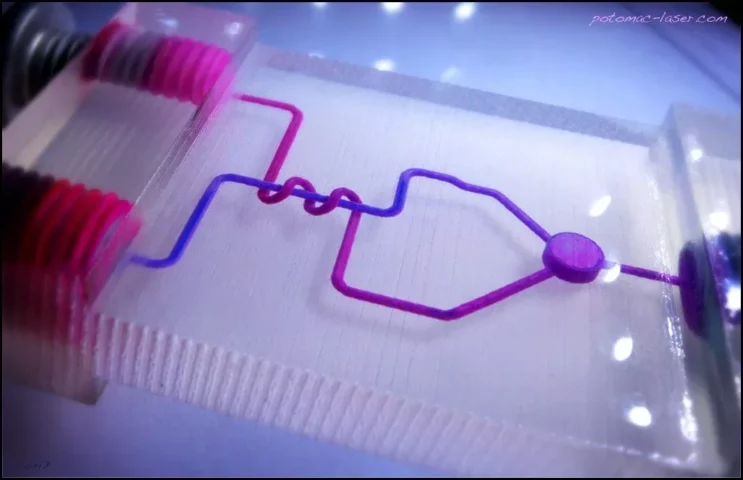

Custom Micro Parts – Delivered Fast

At Microfabrication company Potomac Photonics, we prioritize speed without sacrificing quality, ensuring the fastest turnaround in the industry for micro-manufacturing — because we understand that getting your parts swiftly is as crucial as making them precisely

Email us your drawings today!

At Potomac Photonics, we streamline the process of turning your designs into reality, from prototypes to full-scale production. Simply email us your drawings, and our team will quickly create precision parts to meet your exact specifications. With our advanced micro-manufacturing capabilities, we ensure fast, high-quality results, so you can stay focused on innovation and growth.

Every Material

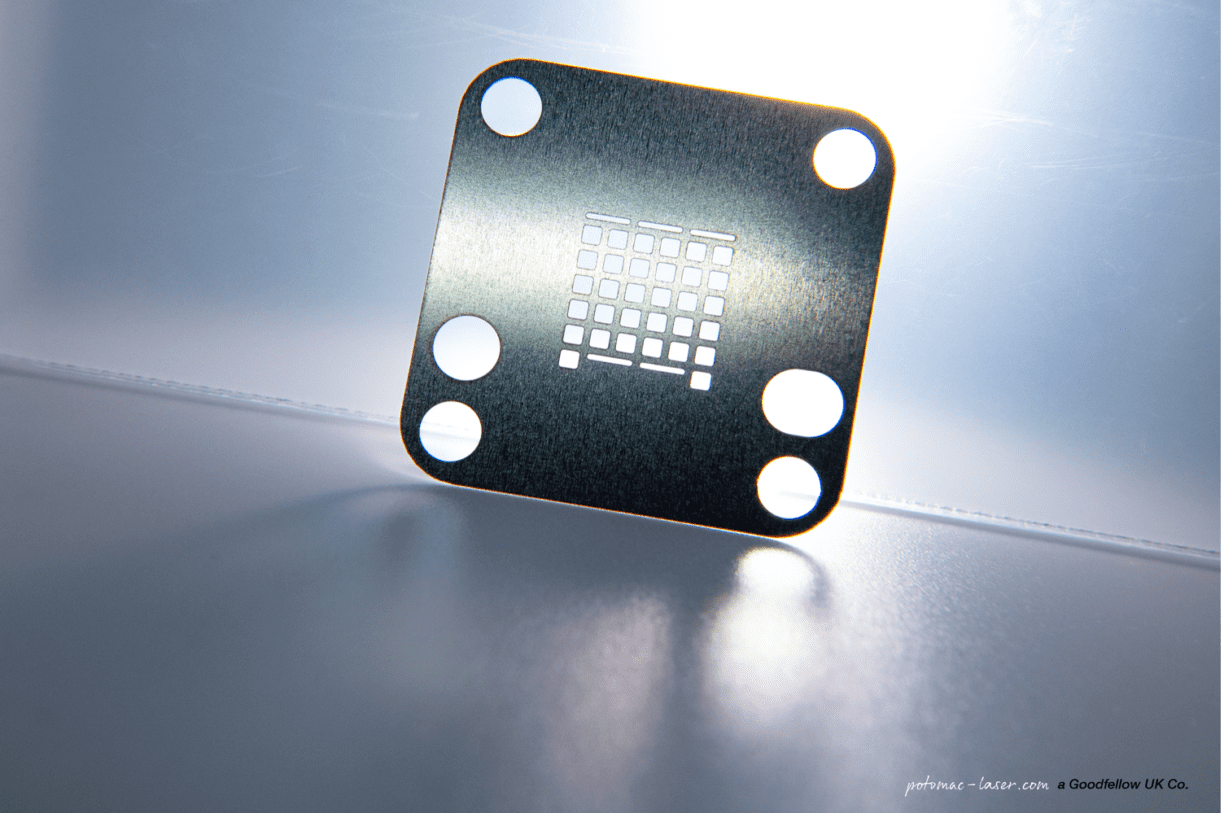

At Potomac Photonics, as part of the Goodfellow family, we have access to over 170,000 materials—virtually every material you could need. Whether it’s metals, polymers, ceramics, or composites, we can machine them all with precision and expertise. No matter your project requirements, our combined resources ensure that you get the right material expertly crafted to meet your exact specifications.

POTOMAC RPM

Reach out to our Rapid Response team today!

You can access customer service for their rapid response and that includes:

WE ARE THE EXPERTS

The Best Parts Start with the Best Materials

The best parts start with the best materials and at Potomac Photonics, now part of Goodfellow, we specialize in crafting precision parts that bring innovative materials to life. With access to over 170,000 high-quality materials from Goodfellow, our micro-manufacturing expertise ensures that your project begins with the best foundation—superior materials and perfectly machined components.

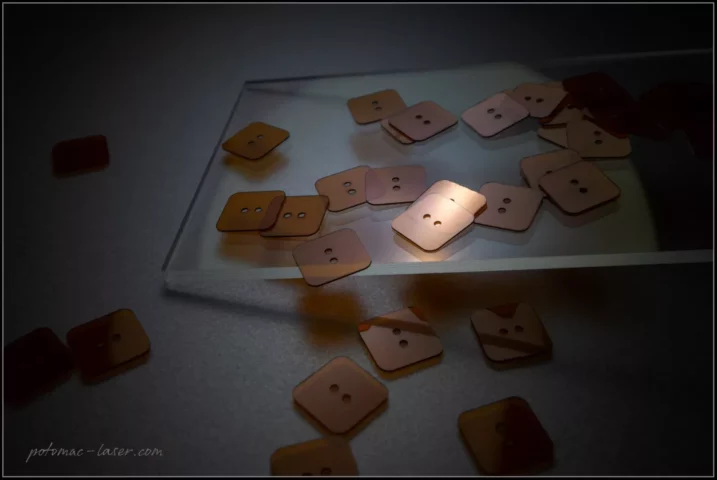

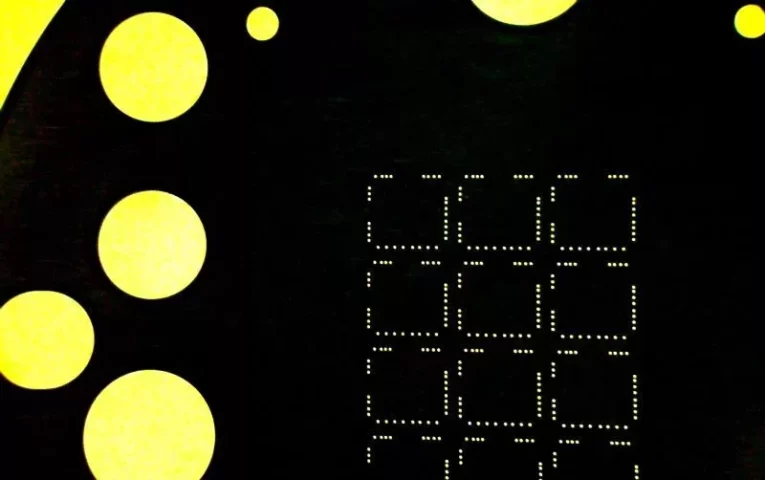

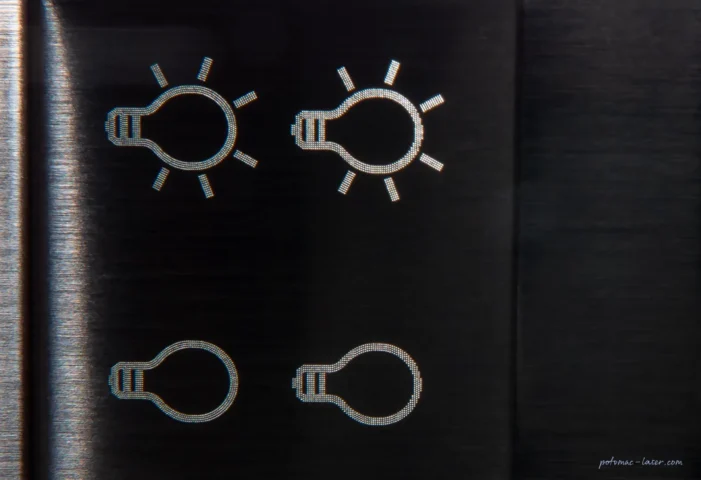

WHAT WE CAN DO

Capabilities

Potomac has been recognized by both commercial and government agencies for innovative contributions to areas such as medical device manufacturing, biotech and electronics fabrication. Its high tech facility is located at bwtech@UMBC Research and Technology Park in Baltimore, MD.

3D DESIGN SERVICES

Leave the design work to us. Exceptional Results. Guaranteed.

We have a team of designers on hand to put your thoughts to life. Our 3D designers work closely with our team of micromanufacturers to ensure accuracy

WHAT WE DO

Our Work speaks for itself

We’ve been doing this for a long time and at a high level. Our process-driven, customer-centric approach as well as our fanatical R&D means that you benefit.

UPDATED ABOUT US

Recent Posts

Since 1982, Potomac has been recognized by both commercial and government agencies for innovative contributions to areas such as medical device manufacturing, biotech and electronics fabrication. Its high tech facility is located at bwtech@UMBC Research and Technology Park in Baltimore, MD.

-

Material Spotlight: DuPont™ Kapton® – A Powerhouse for Micro Manufacturing

VIEW DETAILS: Material Spotlight: DuPont™ Kapton® – A Powerhouse for Micro ManufacturingOver the next few months, we are going to profile different materials that are optimized for micro manufacturing. This includes both rapid prototyping and full scale production. Now that Potomac is part of the Goodfellow family, we are in the…

-

Unleashing Limitless Possibilities: Goodfellow Materials Meet Potomac Photonics’ Precision Micro Manufacturing

VIEW DETAILS: Unleashing Limitless Possibilities: Goodfellow Materials Meet Potomac Photonics’ Precision Micro ManufacturingWhen you pair Goodfellow’s extensive catalog of over 170,000 unique materials with Potomac Photonics’ advanced micro manufacturing technologies, the potential is truly boundless. Picture this: tens of thousands of metal foils and polymer sheets from Goodfellow, available in a diverse…

-

Victory on the Field, Triumph on the Production Floor: Lessons from the Eagles Big Win and Micro Manufacturing

VIEW DETAILS: Victory on the Field, Triumph on the Production Floor: Lessons from the Eagles Big Win and Micro ManufacturingIntroduction We will start with a small confession: living near Baltimore, we wish we were writing about a Super Bowl run by the Ravens rather than the victory of the Eagles. Nevertheless, the lessons from the dominant performance of Philadelphia…

-

Charting New Frontiers: Reflecting on 2024 and Embracing Innovation in 2025

VIEW DETAILS: Charting New Frontiers: Reflecting on 2024 and Embracing Innovation in 2025Reflecting on 2024: One Micron at a Time As the new year begins, we are proud to reflect on all we accomplished in 2024. Over the past year, we produced components that helped send rockets into space, enabled greater range…

OUR CLIENTS

Trusted by leading companies, researchers and entrepreneurs.

Excellent work, fast, and reasonably priced. The shop I used previously left rough edges, visible burning, and significant metal flashing around the edges. Potomac Photonics is in a completely different league and since I’ve started using them, the results have been much better. I’ve had them do everything from precise optical cut-offs to basic mechanical shims in a range of materials. The edges are consistently clean, even under magnification. They have turned orders around much more quickly than I am used to, and most importantly, communication is good. They have taken the time to ask questions to understand my requirements so we can avoid any pitfalls I might miss. I am not an expert in laser cutting so this is very helpful. I would highly recommend them for precision work and quality. Even if you don’t need precision, their prices are still reasonable.

Ben Cramer

Joint Center for Earth Systems Technology. University of Maryland Baltimore County

Thank you so much for helping us with our hummingbird tools. I can’t tell you how much people appreciate the precision of the Tarsus Gauge you all made for us. I just sent some gauges down to Costa Rica and Argentina for researchers there and they are thrilled to be better able to precisely measure and fit bands to their tropical species.

Lee Rogers

Hummingbird Monitoring Network

The resolution of this 3D printer was much higher than what we had in our onsite lab. Working with tolerances in the 1 – 2 thousandths range gave us the parameters we needed to fulfill the design requirement. . . 3D printing can’t always do everything we need, but it is a great tool and has solved some tough problems in our project.

Marton Varady

CryoPop’s Project Manager

We are developing a robotic capsule endoscope which is capable of mobility within the gastrointestinal tract. . . Potomac Photonics produces micro-drilled polyimide sheets that we use as molds to fabricate the micro-patterned polymers. . .

Levin Sliker

Graduate Research Fellow at the University of Colorado Boulder

I could have made these (shadow masks with 10-micron diameter holes) myself in the lab, but the learning curve was high for the size of micro hole drilling we needed. That’s why I sought out Potomac Photonics. Their capabilities allowed me to save the time and energy of doing it myself.

Jean Anne Currivan

MIT Research Assistant

Potomac Photonics expertise and expediency enabled us to both deliver our flight unit calorimeter spectrometer insert on schedule and the opportunity to test in advance our proposed alignment method in Japan.

Meng Chiao

NASA

CONTACT US

Get In Touch

"*" indicates required fields

Reach out to us now

- Our address 1450 South Rolling Road Baltimore MD, 21227 USA

- Call Us 301-310-6527

- Write to us [email protected]