Bacterial infections are becoming much more difficult to treat as they become more resistant to antibiotics. In fact, it is predicted that by 2050 antimicrobial resistance will be more of a crisis to humanity than cancer. If doctors had a way to identify the bacteria faster, they would be able to prescribe a targeted antibiotic rather than a broad-spectrum medication, slowing down the coming of this epidemic.

Currently, the process of determining antibiotic susceptibility is detrimental to patients. Depending upon the situation, a patient must face treatment prior to getting the actual results of an infection test and broad-spectrum antibiotics must be prescribed which often do not kill the specific bacteria or virus. If this process can be shortened, doctors will be able to treat the patient with targeted antibiotics for their specific infection, thereby speeding up recovery while reducing the risk of resistance through advances in biotech.

The Israel Institute of Technology [Technion] has recognized the importance of speeding up antibiotic susceptibility detection, and is developing a Lab-on-a-Chip that will be capable of providing results within 2 hours. This is accomplished using optical sensors that can identify and monitor bacteria much faster than the current technology which uses liquids.

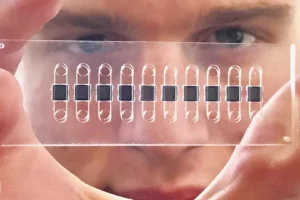

Heidi Leonard who is a PhD candidate under the supervision of Prof. Ester Segal at the Technion Israel Institute of Technology (Ester Segal Lab), reached out to Potomac Photonics, a micro manufacturing company located in the United States, to help build these devices. The challenge was to transition her group’s research from the lab and build an actual microfluidic device as a prototype for the final product. They also wanted to make the devices more ergonomic and economical. With a footprint of just 25mm x 75mm, the Technion Lab-on-a-Chip devices required very small holes, channels and the integration of sensors that are very accurately machined, aligned and assembled.

Potomac Photonics’ micro manufacturing technologies were perfectly suited to build this device accurately, quickly and cost-effectively. Utilizing lasers, micro-CNC machines and custom alignment fixtures, devices that typically can take weeks or even months to fabricate were completed in less than a week. Ms. Leonard commented upon receiving the devices, “There are a lot of technologies out there that sound nice in writing, but when you learn how it’s really being performed, it’s actually quite cumbersome. These devices bring us one very large step closer to using our technology in the hospital.”

Along with the Potomac Photonics engineering team, I was proud to work on this project. Antibiotic susceptibility and resistance has personally affected my family as my mother is a three-time cancer survivor, and often gets sick due to a compromised immune system. She has often had to spend weeks in the hospital recovering from varied bacterial infections. If doctors are able to identify the bacteria faster, this will make her recovery faster and less painful.

Moving forward, Potomac plans to continue to foster innovation in this area. Technion will test the chips that we fabricated for them, and provide us with feedback so that we can eventually build these devices in high volume.

Jacob Adelstein is a junior at Beth Tfiloh High School in Baltimore. He spent time working in the lab at Potomac Photonics on this project, and interviewing the researcher at the Technion about this application.